bending allowance sheet metal With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Buy great products from our terminal junction box Category online at Wickes.co.uk. We supply trade quality DIY and home improvement products at great low prices.

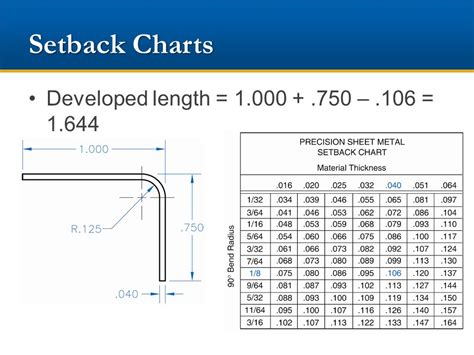

0 · sheet metal setback chart

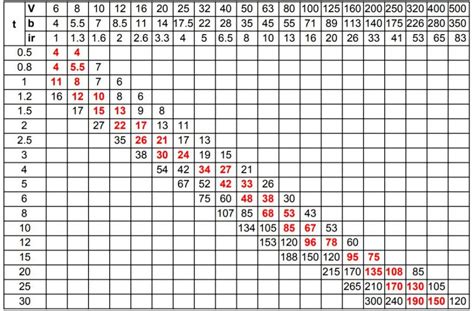

1 · sheet metal bending allowance charts

2 · sheet metal bend calculation formula

3 · how to calculate bending length

4 · how to calculate bending angle

5 · how to calculate bending allowance

6 · calculating bend allowance sheet metal

7 · bend deduction chart for 90

Metal boxes are used more often in commercial construction or where conduit is required. Or as another user mentioned when they will need to support a load like a ceiling fan or heavy light fixture. Plastic is easier to use and cheaper, both qualities you want in residential construction.

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a . Bend allowance is the distance between the points where the metal is bent. This measurement determines how much material needs to be removed in order to create a . Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design . Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This .

Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend .

sheet metal setback chart

The bend allowance is based on the physics of bending metals, not just a random measure. When bending metal, the material inside the bend compresses while the material outside stretches. . Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. . Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . Bend allowance is the distance between the points where the metal is bent. This measurement determines how much material needs to be removed in order to create a smooth, finished product. This sheet metal bend radius calculator can help you quickly and easily determine your project's bend allowance. Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design specifications and quality standards.

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into: Then input the bend angle to get the arc length, bend allowance and bend deduction.

Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator.The bend allowance is based on the physics of bending metals, not just a random measure. When bending metal, the material inside the bend compresses while the material outside stretches. We carefully consider the metal type, thickness, and bend radius to ensure precise manufacturing of our products. Measuring Bend allowanceUse SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges.

Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . Bend allowance is the distance between the points where the metal is bent. This measurement determines how much material needs to be removed in order to create a smooth, finished product. This sheet metal bend radius calculator can help you quickly and easily determine your project's bend allowance. Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design specifications and quality standards. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into: Then input the bend angle to get the arc length, bend allowance and bend deduction.

Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.

The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator.The bend allowance is based on the physics of bending metals, not just a random measure. When bending metal, the material inside the bend compresses while the material outside stretches. We carefully consider the metal type, thickness, and bend radius to ensure precise manufacturing of our products. Measuring Bend allowance

sheet metal bending allowance charts

The stars are in effect giant washers. They are there to keep long metal bolts from slipping through the bricks. This method of running a long bolt through the house and securing it at the ends is a way of keeping old brick buildings from swaying and crumbling.

bending allowance sheet metal|how to calculate bending length