compound curve sheet metal $106.98 At Metko, Inc., we pride ourselves on being leaders in tank manufacturing and custom metal fabrication. With a steadfast commitment to excellence and innovation, we serve industries across Wisconsin and beyond, delivering high .

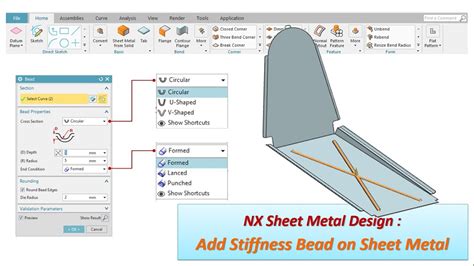

0 · sheet metal stiffness

1 · how to do sheet metal

$17.99

The English wheel is a metalworking tool used for forming smooth, compound curves in sheet metal. It consists of two large wheels – one fixed and one adjustable – that sandwich the metal as it is passed through, gradually shaping it into the desired contour.

9.976.988.99 Arco shows how to quickly shape a panel, 20 ga sheet metal for the front of the SEMA carAmazon store: www.amazon.com/shop/outlawedgePatreon: https://www.patr.

How To Make Compound Curves - YouTube. On this episode of Make It Kustom, I try and duplicate a panel for Jordan’s grill shell using only hand tools. No bead roller, no English wheel, no power. https://www.proshaper.com Our Amazon Storefront: https://www.amazon.com/shop/proshaper How to make a compound curveThis video we're trying something differen.

Dedicated to creating and education on the subject of compound curve sheet metal parts, serving the aircraft, automobile, architectural and art industries from early development . When you start making complex compound curves, where the material is bending in more than one direction at the same time, things get way more complicated. But that doesn’t mean you can’t do them in your own . Join us as we delve into effective methods, from laser cutting to creating compound curves, ensuring every metal sheet transforms into a robust metal part. Ready for some insightful, action-ready tips? Let’s get started.

Learn about a tipping die and the technique used to create curved bends on sheet metal panels, a very simple process.We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. .With years of steel bending expertise, Chicago Metal Rolled Products can create compound curves from the lightest to the heaviest steel sections of structural steel, sheet and plate. Call us with your specific requirements. The English wheel is a metalworking tool used for forming smooth, compound curves in sheet metal. It consists of two large wheels – one fixed and one adjustable – that sandwich the metal as it is passed through, gradually shaping it into the desired contour.

stainless steel cabinet leg levelers

Arco shows how to quickly shape a panel, 20 ga sheet metal for the front of the SEMA carAmazon store: www.amazon.com/shop/outlawedgePatreon: https://www.patr.How To Make Compound Curves - YouTube. On this episode of Make It Kustom, I try and duplicate a panel for Jordan’s grill shell using only hand tools. No bead roller, no English wheel, no power.

https://www.proshaper.com Our Amazon Storefront: https://www.amazon.com/shop/proshaper How to make a compound curveThis video we're trying something differen.

Dedicated to creating and education on the subject of compound curve sheet metal parts, serving the aircraft, automobile, architectural and art industries from early development concept to reproduction of production pieces.

stainless steel cabinet knobs and handles

When you start making complex compound curves, where the material is bending in more than one direction at the same time, things get way more complicated. But that doesn’t mean you can’t do them in your own garage, especially if you can get . Join us as we delve into effective methods, from laser cutting to creating compound curves, ensuring every metal sheet transforms into a robust metal part. Ready for some insightful, action-ready tips? Let’s get started.Learn about a tipping die and the technique used to create curved bends on sheet metal panels, a very simple process.We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! (13) 0 % hE "

With years of steel bending expertise, Chicago Metal Rolled Products can create compound curves from the lightest to the heaviest steel sections of structural steel, sheet and plate. Call us with your specific requirements. The English wheel is a metalworking tool used for forming smooth, compound curves in sheet metal. It consists of two large wheels – one fixed and one adjustable – that sandwich the metal as it is passed through, gradually shaping it into the desired contour. Arco shows how to quickly shape a panel, 20 ga sheet metal for the front of the SEMA carAmazon store: www.amazon.com/shop/outlawedgePatreon: https://www.patr.How To Make Compound Curves - YouTube. On this episode of Make It Kustom, I try and duplicate a panel for Jordan’s grill shell using only hand tools. No bead roller, no English wheel, no power.

sheet metal stiffness

https://www.proshaper.com Our Amazon Storefront: https://www.amazon.com/shop/proshaper How to make a compound curveThis video we're trying something differen. Dedicated to creating and education on the subject of compound curve sheet metal parts, serving the aircraft, automobile, architectural and art industries from early development concept to reproduction of production pieces.

When you start making complex compound curves, where the material is bending in more than one direction at the same time, things get way more complicated. But that doesn’t mean you can’t do them in your own garage, especially if you can get . Join us as we delve into effective methods, from laser cutting to creating compound curves, ensuring every metal sheet transforms into a robust metal part. Ready for some insightful, action-ready tips? Let’s get started.Learn about a tipping die and the technique used to create curved bends on sheet metal panels, a very simple process.We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! (13) 0 % hE "

how to do sheet metal

stainless steel cabinet mushroom

$4.32

compound curve sheet metal|sheet metal stiffness