cnc machine heat extraction hood When designing a hood or verifying if a hood is working optimally, following a few best practices can influence not only how effective the hood is, but also the volume of air required for effective dust capture. Several important . A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings. If you’re not comfortable working with wires and electricity, you should hire an electrician to do this job for you.

0 · The AirPRO Nut dust extraction hood is designed to

1 · MDF dust extraction improvements : r/CNC

2 · Guide to CNC Dust Collection

3 · Enclosure Exhaust System

4 · DUST

5 · Canopy Hoods for CNC Machines

6 · CNC Router Blower: Components, Advantages, and Maintenance

7 · CNC Dust Collection

8 · Best practices for effective dust collection hood design

9 · Best CNC Router Dust Collection System: OUR TOP PICKS

Like standard rectangular boxes, gangable electrical boxes hold household switches and electrical outlets. Still, they are oversized so that two, three, or four devices can be mounted side-by-side. Gangable electrical boxes are often made of durable galvanized steel.

Dust removal can be a time-consuming health and safety problem if the dust extraction on your CNC router is inadequate. The new "AirPRO" from Techniks removes dust from nested cutting operations to keep it from accumulating.Most of the time when I'm running the machine I'll also go close off any hoses that are going to other tools. Our main hose coming out of the collector is about 14" and that goes down to a 6" .dust get captured directly and fed towards the dust extraction of the machine. The turbine greatly improves the removal of chips and keeps the tool a lot cooler!Discover effective dust collection solutions for CNC routers to enhance safety, efficiency, and performance. Learn about different types of dust, health risks, essential components, and best practices for optimal dust collection in CNC.

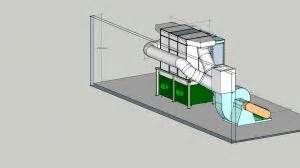

When designing a hood or verifying if a hood is working optimally, following a few best practices can influence not only how effective the hood is, but also the volume of air required for effective dust capture. Several important .Start loading parts sooner, without waiting for the coolant mist to clear from the machine enclosure. The Haas Enclosure Exhaust System keeps the machine’s interior clear of mist and smoke generated during the machining process, .

This is where you get the best and most economical dust shoe for your CNC router. The ABS top plate connects to the router and the removable magnetic skirt allows for easy bit changes. The top plate has a built-in air diverter so the .Canopy Hoods are a pre-engineered hood that encloses a CNC or similar machine to allow for the capture of dust and fumes. Enclosed Capture Hood. Aluminum frame construction with .

discount oem metal fabrication

Track the health of the CNC router dust collector using the differential pressure maintained on either side of the cutter blocks. Wash the pre-filters of the router waste extraction system once a week during period of high-speed routing. Replace HEPA filters based on the CNC machine hours worked and the type of materials machined.Dust removal can be a time-consuming health and safety problem if the dust extraction on your CNC router is inadequate. The new "AirPRO" from Techniks removes dust from nested cutting operations to keep it from accumulating.Most of the time when I'm running the machine I'll also go close off any hoses that are going to other tools. Our main hose coming out of the collector is about 14" and that goes down to a 6" hose on the CNC. Harmful dust and fibers are easily spread into the air when your CNC machine is not set up properly. Find the best dust collector for your CNC will not only save you time and money in the long run, but will also help keep you healthy.

dust get captured directly and fed towards the dust extraction of the machine. The turbine greatly improves the removal of chips and keeps the tool a lot cooler!Discover effective dust collection solutions for CNC routers to enhance safety, efficiency, and performance. Learn about different types of dust, health risks, essential components, and best practices for optimal dust collection in CNC. When designing a hood or verifying if a hood is working optimally, following a few best practices can influence not only how effective the hood is, but also the volume of air required for effective dust capture. Several important design considerations are often overlooked or .Start loading parts sooner, without waiting for the coolant mist to clear from the machine enclosure. The Haas Enclosure Exhaust System keeps the machine’s interior clear of mist and smoke generated during the machining process, improving visibility and allowing for faster workpiece exchange.

This is where you get the best and most economical dust shoe for your CNC router. The ABS top plate connects to the router and the removable magnetic skirt allows for easy bit changes. The top plate has a built-in air diverter so the router motor cooling exhaust is directed horizontally and not down on the work surface.

Canopy Hoods are a pre-engineered hood that encloses a CNC or similar machine to allow for the capture of dust and fumes. Enclosed Capture Hood. Aluminum frame construction with welding curtain panels & (4) eye bolts to allow suspension from the ceiling - 121" x 55" x 32".

Track the health of the CNC router dust collector using the differential pressure maintained on either side of the cutter blocks. Wash the pre-filters of the router waste extraction system once a week during period of high-speed routing. Replace HEPA filters based on the CNC machine hours worked and the type of materials machined.Dust removal can be a time-consuming health and safety problem if the dust extraction on your CNC router is inadequate. The new "AirPRO" from Techniks removes dust from nested cutting operations to keep it from accumulating.Most of the time when I'm running the machine I'll also go close off any hoses that are going to other tools. Our main hose coming out of the collector is about 14" and that goes down to a 6" hose on the CNC. Harmful dust and fibers are easily spread into the air when your CNC machine is not set up properly. Find the best dust collector for your CNC will not only save you time and money in the long run, but will also help keep you healthy.

dust get captured directly and fed towards the dust extraction of the machine. The turbine greatly improves the removal of chips and keeps the tool a lot cooler!

Discover effective dust collection solutions for CNC routers to enhance safety, efficiency, and performance. Learn about different types of dust, health risks, essential components, and best practices for optimal dust collection in CNC. When designing a hood or verifying if a hood is working optimally, following a few best practices can influence not only how effective the hood is, but also the volume of air required for effective dust capture. Several important design considerations are often overlooked or .Start loading parts sooner, without waiting for the coolant mist to clear from the machine enclosure. The Haas Enclosure Exhaust System keeps the machine’s interior clear of mist and smoke generated during the machining process, improving visibility and allowing for faster workpiece exchange.

This is where you get the best and most economical dust shoe for your CNC router. The ABS top plate connects to the router and the removable magnetic skirt allows for easy bit changes. The top plate has a built-in air diverter so the router motor cooling exhaust is directed horizontally and not down on the work surface.

The AirPRO Nut dust extraction hood is designed to

Simplest terms.. a one gang box is a regular outlet or switch with one device.. a 2 gang box is devices stacked next to each other side by side.. like 2 plugs set next to each other sideways.

cnc machine heat extraction hood|MDF dust extraction improvements : r/CNC