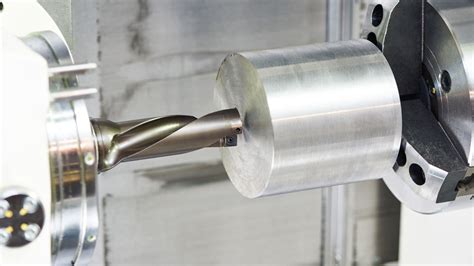

center drill cnc machine The DC-1 is a traditional-style drill/tap machine with a 10,000-rpm BT30 . A low electrical humming noise can be more than just a nuisance. Learn how to find and fix a humming electrical outlet, breaker box, or appliance!In many cases, the cause of a circuit breaking tripping is an overloaded circuit. A circuit overloads when more electrical current is being .

0 · types of cnc drilling

1 · high speed cnc drilling machine

2 · cnc drilling machine manufacturers

3 · cnc drilling machine for metal

4 · cnc drilling and tapping machine

5 · best cnc drilling machines

6 · automatic drilling and tapping machine

7 · automated drilling and tapping machine

It's about durability, safety, and, most importantly, sustainability. Why Stainless Steel Outshines Plastic Durability That Stands the Test of Time: Unlike plastic containers that chip, crack, or stain, stainless steel lunch boxes are built to last, making them a .

Haas DC Series drill centers that combine high-speed capabilities and space-saving footprints to create versatile vertical machining centers suitable for producing high-precision 2D and 3D .The DC-1 is a traditional-style drill/tap machine with a 10,000-rpm BT30 .

Drill/Tap/Mill Series machines are high-speed, lean-style machining centers with .

Center drills are primarily used to create a tapered feature in the end of a part or .The DC-1 is a traditional-style drill/tap machine with a 10,000-rpm BT30 spindle and high-speed turret-style tool changer to minimize cut-to-cut times and shorten cycle times. Choose the optional 15,000-rpm or 20,000-rpm spindle to cut .FANUC’s ROBODRILL Plus is a vertical machining center available in standard as well as advanced small, medium and large models. Get a quote today!

Haas DC Series drill centers that combine high-speed capabilities and space-saving footprints to create versatile vertical machining centers suitable for producing high-precision 2D and 3D parts, such as those found in the communications, aerospace, medical, and automotive industries.

The DC-1 is a traditional-style drill/tap machine with a 10,000-rpm BT30 spindle and high-speed turret-style tool changer to minimize cut-to-cut times and shorten cycle times. Choose the optional 15,000-rpm or 20,000-rpm spindle to cut production times even further.

FANUC’s ROBODRILL Plus is a vertical machining center available in standard as well as advanced small, medium and large models. Get a quote today! Choosing the correct size and angle for a center drill is crucial for optimal performance, with drill charts and sets providing guidance for appropriate selection based on application requirements.

CNC Drilling and Routing Machining Centers DRILLTEQ V-200 A flexible all-rounder for processing in just 5 m² These versatile machines can be used for drilling, trimming and grooving, offering the ideal solution to save you time, space, energy and money.With FlexBEAM technology businesses can accurately drill holes in a variety of steel profiles at different lengths with CNC-controlled programming. This machine will eliminate the manual layout process and help to eliminate costs and errors. Contact us today to learn more A center drill is used for drilling a hole on the axis of a shaft to hold it between centers. It was also used to drill center holes on machining centers, but has been replaced by the spot drill (which has a simpler geometry) for this purpose.At Absolute Machine Tools, we proudly offer vertical CNC drill/tap centers from renowned and trusted manufacturers in the industry. Our extensive selection ensures that you’ll find the perfect machine to meet your specific needs.

types of cnc drilling

Drill/Tap/Mill Series machines are high-speed, lean-style machining centers with compact footprints that make very efficient use of valuable shop floor space.

high speed cnc drilling machine

Center drills are primarily used to create a tapered feature in the end of a part or stock to provide a secure contact point for a live or dead center. The straight pilot drill section starts the hole, and provides clearance for the point of the center, so it does not contact the bottom of the hole.Haas DC Series drill centers that combine high-speed capabilities and space-saving footprints to create versatile vertical machining centers suitable for producing high-precision 2D and 3D parts, such as those found in the communications, aerospace, medical, and automotive industries.The DC-1 is a traditional-style drill/tap machine with a 10,000-rpm BT30 spindle and high-speed turret-style tool changer to minimize cut-to-cut times and shorten cycle times. Choose the optional 15,000-rpm or 20,000-rpm spindle to cut production times even further.FANUC’s ROBODRILL Plus is a vertical machining center available in standard as well as advanced small, medium and large models. Get a quote today!

Choosing the correct size and angle for a center drill is crucial for optimal performance, with drill charts and sets providing guidance for appropriate selection based on application requirements.

CNC Drilling and Routing Machining Centers DRILLTEQ V-200 A flexible all-rounder for processing in just 5 m² These versatile machines can be used for drilling, trimming and grooving, offering the ideal solution to save you time, space, energy and money.With FlexBEAM technology businesses can accurately drill holes in a variety of steel profiles at different lengths with CNC-controlled programming. This machine will eliminate the manual layout process and help to eliminate costs and errors. Contact us today to learn more

A center drill is used for drilling a hole on the axis of a shaft to hold it between centers. It was also used to drill center holes on machining centers, but has been replaced by the spot drill (which has a simpler geometry) for this purpose.

At Absolute Machine Tools, we proudly offer vertical CNC drill/tap centers from renowned and trusted manufacturers in the industry. Our extensive selection ensures that you’ll find the perfect machine to meet your specific needs.Drill/Tap/Mill Series machines are high-speed, lean-style machining centers with compact footprints that make very efficient use of valuable shop floor space.

cnc insert manufacturers in india

cnc internal grinding machine palmary.com

cnc drilling machine manufacturers

But you're absolutely correct. Metal boxes are well optimized to have blank covers. You can "dial the cubic inches" by bumping up to 4-11/16" or 6" metal boxes, or by stacking extension boxes, or by using domed covers or mud rings .

center drill cnc machine|high speed cnc drilling machine