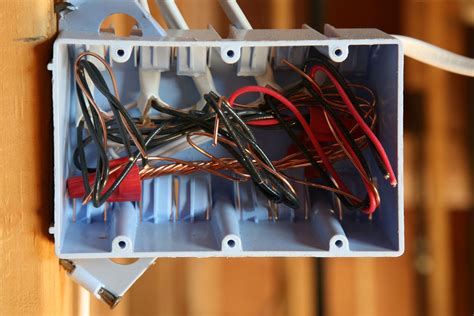

plastic versus metal junction box A locknut-type clamp is the classic metal cable clamp with a short, threaded . $1,239.00

0 · wiring plastic electrical boxes

1 · wiring plastic electrical box knockouts

2 · plastic vs metal electrical boxes

3 · plastic outlet box vs metal

4 · plastic junction boxes electrical lowe's

5 · metal vs plastic gang box

6 · junction box vs outlet

7 · grounding metal electrical boxes

$8.88

Strong, fireproof, and incapable of melting, metal boxes offer the greatest level of security for all electrical wiring applications. Compared to plastic boxes, metal electrical boxes are very strong: It is virtually impossible to bend, warp, twist, or crush metal electrical or junction .15 amps: A cable labeled "14-2 with ground" will have two insulated conductors with .BX cable is a type of metal-clad, armored cable. Learn the basics of armored BX .A locknut-type clamp is the classic metal cable clamp with a short, threaded .

Metal Junction Box: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term. Plastic Junction Box: Plastic .

Electrical boxes come in two primary materials: plastic and metal. Plastic junction boxes are lightweight, affordable, and resistant to corrosion. They are suitable for dry environments. Metal junction boxes are more durable, they . Metal boxes need a proper depth plaster ring and make it harder when a DIY cuts the drywall due to the rounded edges. Plastic boxes and NM are about twice as fast to install over metal. Plastic have the built-in nail vs . Discover the pros and cons of plastic vs metal junction boxes. Learn which is better for your electrical projects based on durability, safety, and cost. 12K. 748K views 11 months ago. All My Favorite DIY Electrical Tools - https://www.amazon.com/shop/everydayh. Do you feel comfortable using metal electrical .

The four types of electrical boxes are: plastic, metal, weatherproof, and junction. Plastic and metal boxes are the most common, while weatherproof and junction boxes are used in specific applications. Source: Jatumeth Susukh/ Shutterstock.com Metal vs. Plastic Junction Boxes There are two types of junction boxes in common use today: metal junction boxes and plastic junction boxes.Both have their own . The use of plastic electrical boxes on metal studs can generally be allowed, but it is advisable to consult your local code enforcement regulations for specific guidelines. Should junction boxes be metal or plastic? Junction boxes . Plastic versus Metal Junction Box. Jump to Latest 21 - 31 of 31 Posts. 1 .

how many wires in a round junction box

Metal and plastic are the most common materials used to construct electrical boxes. Metal boxes are primarily made from steel, aluminum, or cast iron, while non-metallic boxes use PVC or fiberglass. Is it beneficial to replace the metal electric box with plastic? Metal boxes were the standard in the market before the advent of plastic . [left]Hi all. 60 amp sub panel, detached bldg. 75 feet #6 four-wire underground. Two-rod ground at building. On startup i measured 116v on each hot to neutral but hot to hot only reads 201v. volts at outlet is 116v. Key Differences Between Plastic and Metal Junction Boxes. You can choose between plastic and metal junction boxes depending on your project needs. Let’s examine the main differences. Durability and Strength. One of the most significant differences between plastic and metal junction boxes is their strength.

A junction box is a protective enclosure where electrical wires meet to distribute power to your ceiling lights, outlets, switches, and appliances. This box protects connections to minimize the risk of sparking or overheating wires that can lead to fires, especially in spaces with insulation or other flammable materials. Purpose of a Junction Box A junction box is designed .Metal boxes are compatible with metal clad wires. Metal boxes have better shallow options and can easily be combined to make multigang options not available in plastic. Plastic boxes are cheaper and faster to work with but not so much so that it's worth an extra trip to a supply house. Commercial work there is no choice. We use metal boxes. I need to install a junction box for 240V going to two separate Thermostats for baseboard heaters (one 750W and another 1100W). Should Does NEC require that I use plastic or metal boxes for the thermostats and junction box? I .

All My Favorite DIY Electrical Tools - https://www.amazon.com/shop/everydayhomerepairs Do you feel comfortable using metal electrical boxes on your DIY elect.

I prefer em because the connectors fit better, they mount without flexing or distortion, and mounting the box flush to the stud with the appropriate size mud ring is easier than mounting the plastic box with the exact 1/2” or 5/8” extension from the stud face. Re: Plastic vs metal junction box? Post by Rodango » Sat Sep 28, 2019 2:02 pm Metal boxes may take a step or two more to implement, but they will always be stronger of the two, and have better options for clamping nm cable or mt. Plus, that ugly blue.they used to come in dark grey, that was better to look at.Metal: Cheaper here, by about 40%, but boxes aren't a huge cost either way. We prefer to screw from the inside of the box to substrate for improved ease of adjustment later. Metal boxes intrinsically bond the screws so they aren't an unbonded path to substrate. The back box will need to be chased into the walls at both points and as such they must be metal back boxes as the plastic back boxes are for surface mounting only. I can use the plastic back boxes inside the chase so that it’s flush when plastered, however there may be little gaps around the edges as the plastic back boxes are slightly .

Metal cabinets provide a layer of EMI shielding. Basically it is a faraday cage. I'd always want a metal box for my power and control gear. I use plastic junction boxes out on the equipment though to bring a bunch of sensors, actuator cables, etc together into a . Plastic vs metal junction box? Jump to Latest 654 views 2 replies 3 participants last post by Gregsoldtruck79 Sep 21, 2019. H. hardsoftrock Discussion starter 13 posts Metal vs. Plastic Junction Boxes When it comes to junction boxes, the debate often boils down to two materials: metal and plastic. Each has its pros and cons, so let’s break it down! Metal Junction Boxes Pros: Durability: Metal boxes .

wiring plastic electrical boxes

wiring plastic electrical box knockouts

Doesn't matter plastic or metal just use the appropriately sized box for the number of wires. Also use what makes the most sense. If I'm doing a simple junction I use plastic. When I have a lot of wires I use metal, easier to use. Make sure you put a cover on the box when your done. Figure no 3 Plastic junction box. 2) Durability and Longevity: Metal junction box vs plastic Metal Junction Box: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term.; Plastic Junction Box: Plastic junction boxes are not so sturdy, so not suitable for outside .plastic vs. metal junction boxes ; plastic vs. metal junction boxes . J. john_williams1000. Contact options for registered users. posted 18 years ago. Sun, Mar 20, 2005 2:21 AM. In an unused area (such as an attic with no stairway access, not used for storage) I need to make some electrical connections. (Don't worry, my building inspector is .

The box is probably too small for the wire, The wire is cut short, The plastic box is flexed. I would replace that b plastic cover with something else though. They probably have better plastic covers than a crappy wall plate.You cannot hide a junction box in a wall for ot of reasons but if you have access to your attic, putting g the junction box on a stud or rafter close to your light will work. Ypur supposed to keep junction boxes away from the ceiling anyway up on the joists. Metal is best for attic, just ground it properly and your good to go.

If you get a metal box, ensure you have the proper 2 hole strap to secure it. I don't use nm cable much, but it's a 1" or 3/4 knockout. I believe it's 3/4. If you go the plastic route you'll need a box that has a "range input" or something like that that'll fit 6-3 wire. The problems are not specific to an outdoor location. They are for any use. Top 10 reasons metal boxes are better than plastic boxes: Metal completes a circuit. So if a hot wire comes loose, it will short and trip a breaker when it touches the side of the box, letting you know there is a problem and becoming safe in the process.

I'm planning on putting an electrical box in my sink base with a split outlet, one for the dishwasher, the other for the garbage disposal. I was thinking of running 12/3 MC from the wall gangbox (metal box + metal cover with knockout) to another metal box in the sink base. Years ago did some work in a office building built in 1979, wiring was NM cable with suspended ceilings, now prohibited, but whoever wired it ran NM cable to one & two gang nail on plastic boxes on the trusses to supply the lights, they then ran 1/2" steel flex from the boxes to the 2X4 troffers, which each suite had 8 of, with 4-F40 lamps in .

It is great for replacing existing ceiling junction box since most junction boxes are mounted against joist. This box has a metal bracket behind plastic box which makes it strong. Most other plastic boxes I have seen are designed to use wood screws directly into the joist holding the junction box for hanging ceiling fan.

how many explo ammo for sheet metal wall

15 Amp Outdoor Electrical Outlet Box with On/Off Switch and Indicator Light, 125 Volt NEMA 5-15 Duplex Receptacle, Grounding, IP66 Waterproof Wall Power Socket, Weather and Tamper Resistant

plastic versus metal junction box|junction box vs outlet