sheet metal means Hand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The . See more Here are the top 10 tools that every metal fabrication shop needs to have: 1. Welding Machine. A welding machine is an essential tool for metal fabrication. It allows fabricators to join metal pieces together using various welding techniques, such as MIG, TIG, or stick welding. 2. Plasma Cutter.

0 · what is sheet metalworking

1 · types of metal sheets

2 · steel sheet price per kg

3 · sheet metal types list

4 · sheet metal types and grades

5 · sheet metal size chart

6 · sheet metal characteristics

7 · metal sheets at screwfix

An electrical gang box is a small metal or plastic box that encloses electrical wiring. Gang boxes are usually installed where multiple electrical devices will be connected, such as in a home or office.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or . See moreHand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The . See more

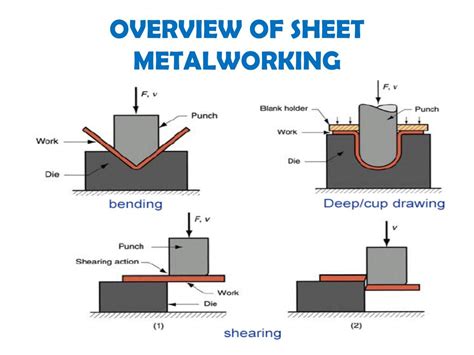

BendingThe equation for estimating the maximum bending force is,$${\displaystyle F_{\text{max}}=k{\frac {TLt^{2}}{W}}}$$,where k is a factor taking into account several parameters . See moreFasteners that are commonly used on sheet metal include: clecos, rivets, and sheet metal screws. See more• "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See more

Stainless steelGrade 304 is the most common of the three grades. It offers good corrosion resistance while . See moreThe use of sheet metal, through a comprehensive cold working process, including bending, shearing, punching, laser cutting, water jet cutting, riveting, splicing, etc. to make the final product we want (such as computer chassis, washing machine shells, . See more

• Circle grid analysis• Corrugated galvanised iron, also known as Corrugated Sheet Metal• Diamond plate• Forming limit diagram See more

noun. : metal in the form of a sheet. Examples of sheet metal in a Sentence. Recent Examples on the . These examples are automatically compiled from online .Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than .

what is sheet metalworking

a4 size metal box

Gauge size chart for sheet metal. Filter for standard steel, galvanized steel, stainless .What is Sheet Metal? Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Countless .

noun [ C or U ] uk / ˈmet. ə l / us / ˈmet̬. ə l / a chemical element, such as iron or gold, or a mixture of such elements, such as steel, that is generally hard and strong, and through which . Sheet metal is one of the shapes and forms metal can be bought in. Sheet metal is any metal that has a thickness in between 0.5.6 millimetres. There are other measurement units used to categorise metals by thickness, .Sheet metal definition: metal in sheets or thin plates.. See examples of SHEET METAL used in a sentence.

Sheet metal, to state the obvious, is metal that has been transformed into sheet form, like a sheet of plywood or a sheet of drywall. Many people equate the term “sheet metal” with the silvery or spangly-looking metal . Different materials have different tolerance requirements during processing. For example: Aluminum Alloy: Due to its softer nature, the typical tolerance range is around ±0.1mm.; Stainless Steel: With its higher hardness, .

abacorp cnc machined parts

We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal . Sheet metal spinning is one of the metal forming processes, where a flat metal blank is rotated at a high speed and formed into an axisymmetric part by a roller which gradually forces the blank . Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the metal in thousandths of an inch.What is the meaning of 120 GSM sheet? Generally while defining galvanized iron (GI) sheets, this term is used. Here GSM stands for grams per square meter. 120 GSM means one square meter of sheet is having 120 grams of galvanized iron coating .

The incremental forming of metal sheet parts can be an interesting alternative to the manual forging of the blanks or to the manufacturing of resin dies for the production of prototypes or small .When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the

SMART, the International Association of Sheet Metal, Air, Rail and Transportation Workers, is one of North America’s most dynamic and diverse unions with 230,000 members. SMART’s members produce and provide the vital services that move products to market, passengers to their destinations and ensure the quality of the air we breathe. We are sheet metal [.]The K-Factor in sheet metal working is the ratio of the neutral axis to the material thickness. . For our example this means a bend at the 2” mark. Once you’ve bent your sample pieces carefully measure the flange lengths of each piece. Record each length and take the average of lengths. Sheet metal cutting, an intricate process that shapes the backbone of numerous industries, stands as a testament to human ingenuity in manufacturing. This . Metal Cutting Process: Definition, Types & Applications What is Metalworking: Definition, History, Types & Applications Water Jet Cutting Edge Quality .

The incremental forming of metal sheet parts can be an interesting alternative to the manual forging of the blanks or to the manufacturing of resin dies for the production of prototypes or small lots of parts. Indeed, the characteristics of small-volume production would call for an increase in the level of automation, possibly leading to a robotized cell able to complete .Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Bends. Bends in sheet metal are manufactured using sheet metal brakes. A +/- 1 degree tolerance on all bend angles. With new technology and equipment being created all the time, the number of ways sheet metal can be used is only increasing, meaning the benefits of using it are increasing too. Now the design tools that are run by computers can cut, shape, and bend sheet metal to exact measurements—much more precisely than even the best-trained humans could do.Sheet Metal definition: Metal that has been rolled into a sheet having a thickness between foil and plate.

Definition: Sheet metal is a flat, thin piece of metal formed through an industrial process. It’s characterized by its high surface area to volume ratio, which allows it to be bent, cut, and shaped into various forms. Characteristics: Typically, .

Secure websites use HTTPS certificate. A lock icon ( ) or https:// means you’ve safely connected to the official website. Share sensitive information only on official, secure websites.

Define sheet metal. sheet metal synonyms, sheet metal pronunciation, sheet metal translation, English dictionary definition of sheet metal. n. Metal that has been rolled into a sheet having a thickness between foil and plate. sheet′-met′al adj. American Heritage® Dictionary of the English.

A Sheet Metal Worker, or Sheet Metal Technician, works with thin sheets of metal to produce and install various types of products. On a typical Sheet Metal Work job description, their listed duties may include measuring and marking raw materials, cutting sheet metal to desired sizes using specialized equipment and fastening sheet metal into place via soldering, . Sheet metal fabrication, the practice of manipulating flat pieces of metal into new shapes, is a practical and low-cost solution for making parts like. Get Quote. . (width) and short transverse (thickness). These elongated crystals have important effects on the behavior of the metal. The mean size of each crystal, or the metal’s grain size, .

Sheet metal screws can be used in a wide variety of ways. Learn more about the different types and uses of sheet metal screws. Call us today! 800.483.6354. Menu. . All Points Fasteners gives you a sheet metal screw definition, along with its different types and how to use them. We provide enough guidance to eliminate the guesswork when you .(13) "Sheet metal work" means the onsite layout, installation, erection, replacement, repair or alteration, including, but not limited to, onsite testing and balancing of related life safety components, environmental air, heating, ventilating and air conditioning systems by manipulating, adjusting or controlling such systems for optimum balance . Sheet metal gauge charts may seem like just numbers, but they’re vital for precision in manufacturing. Understanding these gauge numbers, which indicate material thickness in millimeters or thousandths of an inch, is crucial for selecting the right sheet metal for your project. Dive in to explore how gauge numbers vary by material and .

Confused by sheet metal processing terminology? Our guide offers a comprehensive list of 71 key terms and definitions to help you navigate the world of sheet metal fabrication with confidence. AWS D9.1/D9.1M:2018 – Sheet Metal Welding Code: This specific code addresses the arc and braze welding requirements for nonstructural sheet metal fabrications. It encompasses commonly welded metals available in sheet form and includes requirements and limitations governing procedure, performance qualification, workmanship, and inspection .

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking Operations Standard specification for steel sheet, metallic-coated by the hot-dip process for corrugated steel pipe. A930 – 09(2020) Standard practice for life-cycle cost analysis of corrugated metal pipe used for culverts, storm sewers, and other buried conduits. A964 / A964M – 17. Standard specification for corrugated steel box culverts Sheet metal notching: Tube notching: Process mechanism: A punch press is used in removing unwanted materials on the sheet edges. In tube notching, different angle cutting are made on the metal tube. . Additionally, the blade being automated means that there is time conscience and perfect cuts without blurs. Machine should be secure;

types of metal sheets

aberdeen file in gray steel laminate hanging box file

What Is a Distribution Box? The distribution box is a small box that comes after the septic tank but before the drain field. They're usually made of either plastic or concrete, and they have several openings on different sides .

sheet metal means|sheet metal types list