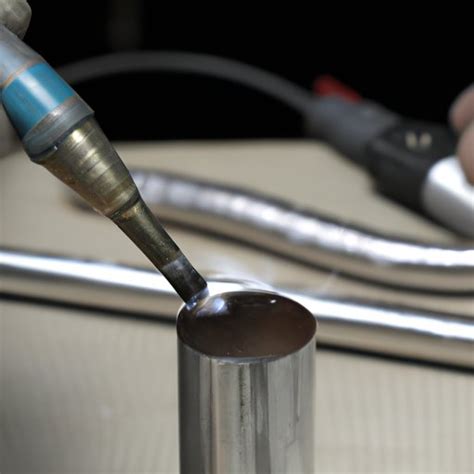

brazing sheet metal together Brazing is a straightforward, six-step process used extensively by fabrication shops to join dissimilar metals. Each step in the process is relatively simple, but skipping any one of them can undermine the entire production .

Level up your productivity and profit with our quality CNC horizontal machining centers (HMCs). Horizontal machining centers spend more time cutting per shift than VMCs and require less operator intervention. Our HMCs can be configured and optimized to successfully handle your most challenging applications.

0 · metal brazing pros and cons

1 · how to braze metal together

2 · how strong is brazing

3 · can you braze galvanized steel

4 · brazing strength vs welding

5 · brazing steel with propane torch

6 · brazing stainless steel with propane

7 · brazing stainless steel sheet metal

Shop metal shelf brackets available in many styles: floating, heavy duty, angle, and hook supports in several colors. Made in USA. Create strong shelves today!

Similar to soldering but at higher temps, brazing joins two pieces of metal to form one strong joint. Learn how to braze metal with a Bernzomatic torch here. To braze weld sheet metal, you’ll need a torch (either oxyacetylene or propane), a filler metal (such as a brazing rod or wire), a flux (to help clean and prepare the joint), and appropriate safety gear, such as .

Brazing is the process of joining two independent pieces of metal to form one load-bearing solid joint. Brazing operation is used to join most metals and alloys commonly used in engineering. It is a thermal joining process in . Brazing is the process of joining two pieces of metal together by heating them (usually up to around 850-900 degrees Celsius) and then applying a filler material, known as “brazing alloy” or “brazing rod”, which melts at a lower .Brazing is a method of joining two pieces of metal together with a third, molten filler metal. Of all the methods available for metal joining, brazing may be the most versatile. The process is . Brazing is a straightforward, six-step process used extensively by fabrication shops to join dissimilar metals. Each step in the process is relatively simple, but skipping any one of them can undermine the entire production .

Use these easy steps and procedures on how to braze metal to create solid joints like a pro: Scrub the metal surface using a wire brush or emery cloth. Then use soapy water or a degreaser to clean the metal surfaces. Place the metal in an .

Brazing, like welding, joins two metal pieces together. Unlike welding, brazing uses a filler metal to form a robust joint, and a flux material to protect the filler. Brazing involves a . Brazing stainless steel sheet metal involves joining two materials together with a brazing alloy. It is a technique that is used for many different applications, such as repairing or strengthening parts made from stainless .

Similar to soldering but at higher temps, brazing joins two pieces of metal to form one strong joint. Learn how to braze metal with a Bernzomatic torch here.

To braze weld sheet metal, you’ll need a torch (either oxyacetylene or propane), a filler metal (such as a brazing rod or wire), a flux (to help clean and prepare the joint), and appropriate safety gear, such as goggles and gloves.

Brazing is the process of joining 2 pieces of metal together using a molten filler that is heated and melted and then allowed to flow in to the joint where it then cools and forms the joint. In this guide we take a look at how to braze metal using a blow torch, read on below to find out how. Brazing is the process of joining two independent pieces of metal to form one load-bearing solid joint. Brazing operation is used to join most metals and alloys commonly used in engineering. It is a thermal joining process in which a molten brazing filler metal is drawn into a capillary gap between the metals being joined.

Brazing is the process of joining two pieces of metal together by heating them (usually up to around 850-900 degrees Celsius) and then applying a filler material, known as “brazing alloy” or “brazing rod”, which melts at a lower .Brazing is a method of joining two pieces of metal together with a third, molten filler metal. Of all the methods available for metal joining, brazing may be the most versatile. The process is relatively fast and economical, requires relatively low temperatures and is highly adaptable to automation and lean manufacturing initiatives.

Brazing is a straightforward, six-step process used extensively by fabrication shops to join dissimilar metals. Each step in the process is relatively simple, but skipping any one of them can undermine the entire production process, wasting materials as well as valuable time.Use these easy steps and procedures on how to braze metal to create solid joints like a pro: Scrub the metal surface using a wire brush or emery cloth. Then use soapy water or a degreaser to clean the metal surfaces. Place the metal in an appropriate position for .

Brazing, like welding, joins two metal pieces together. Unlike welding, brazing uses a filler metal to form a robust joint, and a flux material to protect the filler. Brazing involves a simple six-step process: Create a good fit with the right clearances.

metal brazing pros and cons

how to braze metal together

Specialty Stainless offers top-notch stainless steel cabinetry, elevating your space with unparalleled quality and style. Our custom stainlees steel cabinets and doors are crafted with precision, utilizing high-grade stainless steel that enhances .

brazing sheet metal together|how strong is brazing