diy mini cnc machine part 1 New Diy Mini cnc v2 : https://www.youtube.com/watch?v=8g6kYxff_C0&feature=youtu.beparts : 3 DVD Driver2 Screw 5 cm length 6 mm diameter4 Screw 2.5 cm lengt. Generally dies are classified according to their use like stamping dies are used in press working, casting dies used in molding processes, and drawing dies are used in the manufacture of wires. Read also: 9 Types of Sheet Metal Operations with Diagrams

0 · small cnc for house

1 · mini cnc drawing machine

2 · make your own cnc mill

3 · homemade cnc milling machine

4 · diy small cnc mill

5 · diy mini cnc machine

6 · diy cnc mill kit cost

7 · build your own milling machine

Box channels find extensive use in the construction of frames, supports, and bracings for machinery, equipment, and structural components. Back-to-back channels consist of two parallel C-channels that are connected back-to-back. This configuration offers increased strength and load-bearing capacity compared to single channels.

Please Support My Channel, Kindly subscribe and like my videos.So I can do more :)Stay tune! for the next part which is the electronics and hardware installa. Hello friends, in this video series i'll be making a small benchtop CNC router for hobby works. You will find all the measurements and material names at the .

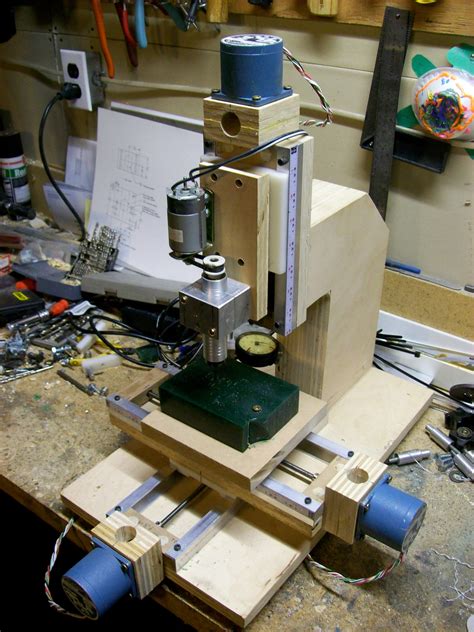

In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill .The Mini CNC project is a complete set of plans and instructions on how to build a 3 axis CNC machine that is functional and also precise. The Mini CNC is very . New Diy Mini cnc v2 : https://www.youtube.com/watch?v=8g6kYxff_C0&feature=youtu.beparts : 3 DVD Driver2 Screw 5 cm length 6 mm diameter4 Screw 2.5 cm lengt.Learn about the best donor mills for a benchtop CNC mini mill in part 1 of this guide to building your own ultimate benchtop CNC machine.

I decided to build a miniature milling machine for machining plastic parts, creating wax patterns and for drilling really small precise holes. I also wanted to design it so that I could convert it to CNC for machining circuit boards and for doing .

New project announcement video! Decided my next project is to build an awesome CNC mini lathe, super compact and super accurate is the plan! This video shows my preliminary design and goes through all my thoughts on . Take two old DVD players, one Arduino Nano and a piece of PVC tubing and build a miniature CNC machine with these parts. Details are given in four videos.

Fortunately, with the right skills and resources, it is possible to build your own DIY small CNC machine. In this blog post, we will guide you through the step-by-step process of building your .

Please Support My Channel, Kindly subscribe and like my videos.So I can do more :)Stay tune! for the next part which is the electronics and hardware installa.

Hello friends, in this video series i'll be making a small benchtop CNC router for hobby works. You will find all the measurements and material names at the .In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill to have at home during the pandemic.

The Mini CNC project is a complete set of plans and instructions on how to build a 3 axis CNC machine that is functional and also precise. The Mini CNC is very simple and easy to build and if you have all the materials and parts prepared you should have it . New Diy Mini cnc v2 : https://www.youtube.com/watch?v=8g6kYxff_C0&feature=youtu.beparts : 3 DVD Driver2 Screw 5 cm length 6 mm diameter4 Screw 2.5 cm lengt.

Learn about the best donor mills for a benchtop CNC mini mill in part 1 of this guide to building your own ultimate benchtop CNC machine.I decided to build a miniature milling machine for machining plastic parts, creating wax patterns and for drilling really small precise holes. I also wanted to design it so that I could convert it to CNC for machining circuit boards and for doing repetitive work.

New project announcement video! Decided my next project is to build an awesome CNC mini lathe, super compact and super accurate is the plan! This video shows my preliminary design and goes through all my thoughts on the engineering behind it. Heavy inspiration taken from hlaps1990 (Greg) his micro lathe is an amazing machine and [.] Take two old DVD players, one Arduino Nano and a piece of PVC tubing and build a miniature CNC machine with these parts. Details are given in four videos.Fortunately, with the right skills and resources, it is possible to build your own DIY small CNC machine. In this blog post, we will guide you through the step-by-step process of building your own CNC machine, from sourcing materials to programming the machine. Chapter 1: Understanding CNC Machines . Introduction to CNC machines

Please Support My Channel, Kindly subscribe and like my videos.So I can do more :)Stay tune! for the next part which is the electronics and hardware installa.

Hello friends, in this video series i'll be making a small benchtop CNC router for hobby works. You will find all the measurements and material names at the .In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill to have at home during the pandemic.

The Mini CNC project is a complete set of plans and instructions on how to build a 3 axis CNC machine that is functional and also precise. The Mini CNC is very simple and easy to build and if you have all the materials and parts prepared you should have it . New Diy Mini cnc v2 : https://www.youtube.com/watch?v=8g6kYxff_C0&feature=youtu.beparts : 3 DVD Driver2 Screw 5 cm length 6 mm diameter4 Screw 2.5 cm lengt.

Learn about the best donor mills for a benchtop CNC mini mill in part 1 of this guide to building your own ultimate benchtop CNC machine.I decided to build a miniature milling machine for machining plastic parts, creating wax patterns and for drilling really small precise holes. I also wanted to design it so that I could convert it to CNC for machining circuit boards and for doing repetitive work. New project announcement video! Decided my next project is to build an awesome CNC mini lathe, super compact and super accurate is the plan! This video shows my preliminary design and goes through all my thoughts on the engineering behind it. Heavy inspiration taken from hlaps1990 (Greg) his micro lathe is an amazing machine and [.]

Take two old DVD players, one Arduino Nano and a piece of PVC tubing and build a miniature CNC machine with these parts. Details are given in four videos.

small cnc for house

mini cnc drawing machine

motor_enclosures.pptx - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Motor enclosures protect motors from environmental contaminants and affect cooling. There are open and totally enclosed enclosures.

diy mini cnc machine part 1|build your own milling machine