fusion 360 sheet metal thickness It is possible to correctly model a sheet metal component using Fusion’s Solid . $48.56

0 · fusion 360 unfold sheet metal

1 · fusion 360 sheet metal tutorial

2 · fusion 360 sheet metal rules

3 · fusion 360 sheet metal drawing

4 · fusion 360 sheet metal cone

5 · fusion 360 sheet metal basics

6 · fusion 360 flange sheet metal

7 · fusion 360 create flat pattern

An extraordinary collection of long-life metal roofing, metal shingles, and metal siding. Direct delivery to homeowners, contractors, and businesses across America.

How do I change the thickness of the sheet metal I'm using ? I picked Steel and it has a thickness 2.5mm and I want 1mm.Issue: How to edit a sheet metal rule or create a new one in Fusion. A new .The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet .It is possible to correctly model a sheet metal component using Fusion’s Solid .

Click on the Sheet Metal tab to activate the Sheet Metal environment. Select Create . Issue: How to edit a sheet metal rule or create a new one in Fusion. A new thickness value may be desired. Solution: Switch rules in an existing design. Click the Sheet . Hi, just wondering if anyone knows if there's a way to automatically include sheet metal thickness in my 2d drawings from design? So far the only way I've been doing it is just manually adding thickness using text. Learn fusion 360 sheet metal basic tutorial for beginner how to create new rule and change thickness, check it out!!!Don't forget guys, if you like our video.

I am trying to use two different thicknesses on different sheet metal parts in the same project. I have mostly 1mm parts, as specified in the project sheet metal rule, but Fusion 360 won't let me use 2mm on another, separate .The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet metal. Learn to create flat patterns from 3D models, work with all sorts of bends, customize your materials, .It is possible to correctly model a sheet metal component using Fusion’s Solid Modeling tools, however, it will not flatten. This is because Fusion 360 assigns a Sheet Metal Rule when the . In this video, we'll start exploring how to use the built-in sheet modeling tools in Fusion 360 to create models designed for cutting, bending, and manufactu.

The design of our Stainless Steel Glove box holder is now complete; however, we need to confirm the sheet metal details, including the thickness. Let’s take a look at creating a Custom Sheet .Click on the Sheet Metal tab to activate the Sheet Metal environment. Select Create > Convert to Sheet Metal. Select a base face. Note: The face you click on determines the body thickness, so you need to click on a wide, flat area of the . Share Fusion (formerly Fusion 360) issues here and get support from the community as well as the Fusion team. All community This category This board Knowledge base Users Products cancel Turn on suggestions

3. Name the rule and update the material Thickness, K Factor, and Bend radius information to match the Advanced Details provided for each bendable material on the Bending Calculator page.To see the Advanced Details, select your .

fusion 360 unfold sheet metal

Solution: Modify the solid body to be converted. Add a flat area to the body that can be used as a base selection, either using Extrude, Press/Pull, or other design features.Error: Can't calculate body thickness. Select the base face of a valid Sheet Metal body (typically a wide, flat area). Fusion 360 documentation shows these possible causes: Causes: The selected body is not a valid sheet metal body. The selected body has a variable thickness to take as reference for sheet metal thickness. Report issues, bugs, and or unexpected behaviors you’re seeing. Share Fusion (formerly Fusion 360) issues here and get support from the community as well as the Fusion team. . It has a lock icon next to the thickness line in the sheet metal rules. Any ideas on how to get around that locked function? Report. 0 Likes Reply. Message 12 of 14 .

I just started using Fusion 360 recently, and I don't understand what the difference is between solid objects and sheet metal. . (thickness), flange size, clearances, etc. We have a vendor that wanted k for a sheet metal based piece of equipment. I designed my own version with about k of my time, and had it made by a local metalworking . The K-Factor just being one of the biggest details outside of material thickness. My suggestion was to have rules be somewhat similar to appearances. . Right now in Fusion 360 you can create a dxf from a sketch and as a path inside the CAM environment. Cheers, Mike Prom. Reply. Reply. 0 Likes 02-09-2017 08:56 AM @DDMFGCOINC, Dxf export for .I made the Sheet Metal thickness rules favorite, but it doesn't change my user parameter "SheetThickness" if the sheet metal rule is changed. The original sheet thickness dimension from the table above is d2, but if I change the sheet metal rule, Fusion creates another parameter AND dimension (d26 and d27 in my case) for the new rules, instead .A named Sheet Metal Rule (for example: Stainless steel (in) or Aluminium (in)) captures these parameters and applies them by default when you create a new sheet metal body. There are pre-defined sheet metal rules that are stored in the sheet metal library. "In this design" lists any rules that have been selected for the active document.

learned and pass it on to other users that are looking to add sheet metal modeling to their Fusion 360 knowledge base. Sheet Metal Rules Sheet Metal Rules are your way of defining the material that will be used to fabricate the part. You will have to include attributes like material thickness, bend radius, reliefs, K Factor, and more. Users reported that a sheet metal part that was converted from a solid (either imported from a STEP or designed with Solid modeling tools) cannot be unfolded or have a flat pattern created in Fusion. One of the following messages appears when trying to unfold the part or create a flat pattern: The selected stationary entity is not connected to any bends. Please . Share Fusion (formerly Fusion 360) issues here and get support from the community as well as the Fusion team. cancel. Turn on suggestions . and can only comment on what I think would be useful / user friendly. Having parametric sheet metal thickness to me would be very useful. Report. 0 Likes Reply. Message 4 of 6 JBerns. in reply to . To model hems in sheet metal, I'm: - making two successive flanges - extruding away the intervening flat section - joining the bodies to make a 180 degree (e.g.) bend. . Have a tricky question about a Fusion (formerly Fusion 360) feature? Share your project, tips and tricks, ask questions, and get advice from the community. . Hem Thickness .

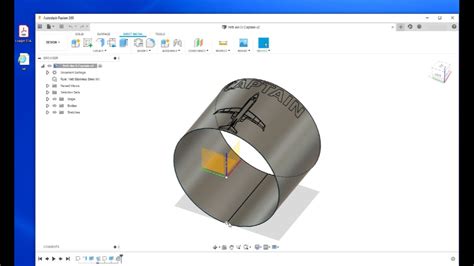

Last year, Fusion 360 software added sheet metal tools to its already large assortment of tools (such as CAM simulation). In this class, we will explore some complex sheet metal components and how the Fusion 360 sheet metal tools can be used to address these complex features like extended flanges, punch tools, and complex flanges.No problem. To be geometrically accurate you have to make sure your material thickness, k factor, and bend radius match. Also keep in mind that Fusion 360 seems to make a copy of the library rules every time you make a component. . Have a tricky question about a Fusion (formerly Fusion 360) feature? Share your project, tips and tricks, ask questions, and get advice from the community. . This is because you first created or imported a solid and .

fusion 360 sheet metal tutorial

Autodesk Fusion 360 does not have a specific command that will allow the creation of conical sheet metal components, but with a little creativity, the process is easy! The first step is to create a constrained sketch of the .Learn how to create different types of sheet metal flanges in the Design workspace in Fusion.. Create a base flange. On the Sheet Metal tab, select Create > Flange.. The Flange dialog displays.. In the dialog, select the Edge Flange type.. In . I've updated F360 today - Maybe I've been staring at the screen for too long, but when trying to cut a profile through a 1.2mm thick sheet metal flange, the flange thickness, and only the flange thickness after the fold, changes itself to 1.4mm ????? Having run and re-run the process I've undone my work to a point it's back to 1.2mm and saved the file - I'll try again in . We have watched and are following the example provided in the 360 Live Tutorial: Creating HVAC parts in Fusion 360 Sheet Metal https: . add thickness. fillet 4 bends. convert to sheetmetal . I seem to end up with individual sections and not a single piece of sheetmetal .

Programmer @CLmoss might disagree with me, but is has been possible to model a sheet metal part in Fusion 360 since day 1. There is nothing special about Fusion sheet metal - simple planar faces connected with either cylindrical or conical faces. Perhaps the most primitive 3D geometry. Fusion 360 Sheet Metal Rules. 1. Must be uniform thickness. 2.

i use on my design 2mm sheet metal. I decided to add a 2.5mm body and convert it on sheet metal. The problem is that although i added this thickness on current design sheet metal rules i get the following error

Welcome to “Fusion 360 Sheet Metal for Beginners!” This free course is brought to you by SendCutSend.com. We’ll look at utilizing Fusion 360’s sheet metal tools to create this Stainless Steel glove box holder. I was able to upload this Fusion 360 design in just a few minutes and three days later the laser-cut stainless steel was at my door.

Thank you for helping me. However, after I create a new sheet metal rule following your video steps and click on the existing rule in my model I don't have the option of changing the sheet metal rule. It just opens up the dialog box showing the existing rule plus the new rule. I wonder why I don't see the option to change / switch sheet metal . I am relatively new to Fusion 360 and I seem to be having a hard time distinguishing between bodies and components. . Can't calculate body thickness. Select the base face of a valid Sheet Metal body (typically a wide, flat area). But when I go to select the object I want, it won't let me. I can attach the drawing, so it will make it easier . Attached is an F360 design in which 3 of 4 identical bends succeed, and the fourth one fails.due to bend interference or uneven thickness. The thickness of the flange is consistent and is controlled by sheet metal rules. This is demonstrated in the attached screencast.

fusion 360 sheet metal rules

fusion 360 sheet metal drawing

Cold Rolled Steel Sheets Offer a Variety of Outstanding Properties, Including Easy formability and a Smooth, Clean Surface, and is Easy to Weld. Only 14 left in stock - order soon.

fusion 360 sheet metal thickness|fusion 360 sheet metal drawing