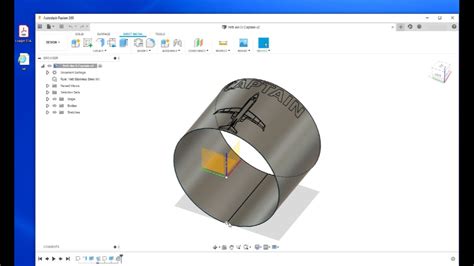

fusion 360 sheet metal drawing In this episode, we'll be modelling a sheet metal bracket, flat-patterning it, and creating a 2D drawing in Autodesk Fusion 360. Bendy metal! Let's get to it. Springback is a semipredictable factor when working with sheet metal. Knowing how to forecast it will allow you to make better tooling selections, especially for profound-radius bends in which springback can exceed 40 degrees.

0 · fusion 360 unfold sheet metal

1 · fusion 360 sheet metal tutorial

2 · fusion 360 sheet metal thickness

3 · fusion 360 sheet metal hem

4 · fusion 360 sheet metal basics

5 · fusion 360 flat pattern drawing

6 · fusion 360 create flat pattern

7 · autodesk fusion 360 sheet metal

From the zigzag post-and-rail of the Colonial era to the elaborate molded vinyl styles of today, fences are homeowners’ preferred means of ensuring privacy and deterring unwanted visitors.

For someone who may be taking that first step into having a sheet metal design created, here are the ESSENTIAL things that your drawing needs before sending it off for .The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet metal. Learn to create flat patterns from 3D models, work with all sorts of bends, customize your materials, . Fusion 360 Sheet Metal for Beginners. Product Design Online. 276K subscribers. In this episode, we'll be modelling a sheet metal bracket, flat-patterning it, and creating a 2D drawing in Autodesk Fusion 360. Bendy metal! Let's get to it.

Use the Flat Pattern tool to create a flat pattern that you can use to create drawings of a sheet metal component for manufacturing in Fusion. A Flat Pattern is the shape of the sheet metal component before it is formed.A new component is added to the Browser, with an icon that looks like a sheet metal part. From the Create group, click Create Sketch, then select the XZ plane. To start drawing the first .Learn about the importance and role of Sheet Metal Rules. Learn how to apply the Flange command to make faces, flanges, and contour flanges. Discover why a sheet metal part may not generate a flat pattern. Learn how to document . In this video, we'll start exploring how to use the built-in sheet modeling tools in Fusion 360 to create models designed for cutting, bending, and manufactu.

In this class, we will explore some complex sheet metal components and how the Fusion 360 sheet metal tools can be used to address these complex features like extended flanges, punch .Sheet metal manufacturing. Learn how to create a sheet metal drawing with a bend table and take the part into CAM to be manufactured using Fusion.Unfortunately, you have to use sheet metal features to create the base model to be able to use sheet metal-specific features like Unfold or the Flat Pattern tool. Using the Flange function to make the bodies guarantees that you have sheet . I've also experienced this same problem with a few sheet metal parts. I've seen plat patterns work in drawings before but the last couple of parts I wanted to do drawings of the flat patterns I had to go in and create a sketch of .

fusion 360 unfold sheet metal

Sheet Metal Rules | Autodesk Fusion 360 | Tutorial (Intermediate)In this episode, we'll be looking at how Sheet Metal Rules work in Autodesk Fusion 360! .

Learn Fusion 360 Sheet Metal in 20 minutes, with this crash-course for beginners. Thanks to our wonderful friends at SendCutSend.com for providing FAST and a. When creating a drawing based on an unfolded sheet metal component, the bend lines neither indicate bend direction, bending radius nor bending angle amount. . Share Fusion (formerly Fusion 360) issues here and get support from the community as well as the Fusion team. cancel. Turn on suggestions. Auto-suggest helps you quickly narrow down .

Learn the foundational concepts of the Sheet Metal workspace in Fusion. See how to create a sheet metal component, use rules to redefine the sheet metal part, and take it to drawings or CAM for manufacturing. Back to Learn & Support. In July 2024, these courses will move to Autodesk Learning - the central, e-learning site for Autodesk products. . How to add flattened sheet metal parts into existing drawing sheets in Fusion 360 Follow the below steps to add the parts into existing drawing sheets. Go to Design from Drawing Sheet workspace. Create a Flat pattern in sheet metal workspace. Go to File and select New Dwarwing option. Select From Design option. Select From Design option and Go to Drawing . Video to some some of the features of the sheet metal environment I want to produce a box, however it isn't possible to produce as one folded part. It will need to be split, into three parts. Is is possible to split into three components, one component needs to be the side with the cut out and the one opposite needs to be a component. I know I produce them separately just wondering if there is a way to split this model? .

fusion 360 sheet metal tutorial

Create drawing view that contains the folded sheet metal body and the flat pattern. In the Create Drawing dialog, select Flat Pattern Representation, and click OK. In the newly created drawing, place the view, and click OK in the Drawing View dialog. Click Base View from the Drawing toolbar, and place the view. The base view of the referenced .

Hey guys,I cannot figure out what the proper way to change the rule for a sheet metal part besides setting it as default and creating a new file. There is no way for me to use 2 rules in 1 document. I think "view rule" should be "change rule" and should allow me to select the rule I'd like to use. Best, -Xander Luciano Hi fellow community members Seek your advise on how to approach this. I've been using Fusion 360 solid functionality primarily, very new to the sheet metal module. Any suggestions on how to draw this? Note that the angles are diagonally sloping. Puzzled 🙂

does house insurance cover damage to electric box

Drawings of flat patterns. You can create drawings from flat patterns. The flat pattern contains a wealth of bend and punch information useful for the creation of manufacturing drawings. The folded sheet metal body can be added to the same sheet as well. If you delete the flat pattern, that view will be lost. User's have asked how to create a flat pattern for a sheet metal part with a non-F3D format (for example: XT, SAT, STEP) that has been imported into Autodesk Fusion. Non-native parts are imported into Fusion as solids or surfaces and need to be converted into sheet metal components before flattening. Follow the steps to be able to create a flat pattern for the .

Creating a cone in sheet metal, which can be flattened for a pattern, is something you'll need to know a trick or two to do. Why? Well - Fusion 360's math as. How to insert multiple sheet metal components into one sheet of drawing. I am looking to include the flat pattern of three designs and multiple views of the design (non-flat pattern). Multiple views (non-flat pattern) - side, .Learn how to add sheets into your current drawing, delete sheets, rename sheets and reorder sheets. Add a sheet. Add a sheet simply by clicking on the + button on the Sheet Bar.. This + button adds a new sheet immediately without .

Thank you for the reply - I was looking to see if there is a quick way to create a perforated pattern correctly. The only experience I have had with this is in Solidworks where there is a 'perforated fill pattern'. Was looking to see if Fusion 360 had a similar work flow for this or if there is a way to do it. CamThe Essential Skills for Sheet Metal Modeling in Fusion 360 Steve Olson MESA Inc. Description Fusion 360 has four unique design workflows, Solid, Surface, Sculpt (T-Spline), and Sheet . component and show how to document the formed part and flat pattern with a 2D drawing. Speaker Steve Olson is the Manager of Training Services at MESA Inc . Need to insert a sheet metal assembly, individual components and flat patterns onto the same drawing sheet in Fusion. To do this: Create an assembly containing sheet metal components. Create flat patterns of the sheet metal components through Sheet Metal > Create > Create Flat Pattern To insert the assembly go to File > New Drawing > From Design and set .

fusion 360 sheet metal thickness

I have created an overall assembly of aluminum folded sheet metal components to make sure it all worked, however now i need to individually create a drawing for each part i have created, but due to it being in sheet metal im really struggling. https://a360.co/2MiG7qh I have attached the file just for reference - basically i need to know how to put P1 on a drawing, P2 on .On the Sheet Metal tab, select Modify > Rip.The Rip dialog displays.; In the canvas, select geometry on a sheet metal flange to place the rip: Face: Select a sheet metal face to remove.; Edge: Select an internal edge to rip along.; Points: Select two points on external edges of the same face to define the start and end point of the rip.; For point and edge selection mode, .

I'm doing a drawing and 1 of the components is a sheet metal component but can't figure out how to make the flat pattern. Can anybody tell me how? Thanks . Have a tricky question about a Fusion (formerly Fusion 360) feature? Share your project, tips and tricks, ask questions, and get advice from the community. . DRAWING: Sheet metal flat . Learn how to design basic sheet metal goods in Autodesk Fusion. We'll discuss using the Flange tool, creating and updating Flat Patterns, sheet metal compone. Many Fusion 360 assembly contain multiple sheet metal components and their flat patterns. In this video I will show a workflow to place all of these flat pa. Fusion 360 sheet metal exercise for beginners | 3D modeling exercise 12 | Complete Step by Step Sheet metal tutorial.Learn the basics of sheet metal design i.

fusion 360 sheet metal hem

fusion 360 sheet metal basics

I'm trying to print out a 1:1 version of a sheet metal design to try out before I commit to spending thousands on a prototype, so I unfolded the design and sent it to a drawing but the bend lines/extents don't show up in the drawing.. how can i get them to show up so I can fold my printed version at.

fusion 360 flat pattern drawing

The red wire typically serves as a secondary live or “hot” wire in 240-volt installations and switch legs. Is the red wire always alive? No, but it’s essential to treat it as live for safety purposes.

fusion 360 sheet metal drawing|fusion 360 flat pattern drawing