metal part fabrication techniques Sheet Metal Fabrication Techniques for Auto Parts. These techniques cut sheet metal parts into smaller pieces of varying dimensions. Laser, plasma, and shearing are common sheet metal auto parts cutting methods. Laser Cutting. Laser cutting is a common sheet metal technique used in automotive manufacturing because of its high precision. $6.99

0 · what are fabricated metal products

1 · types of steel fabrication

2 · types of metal processing

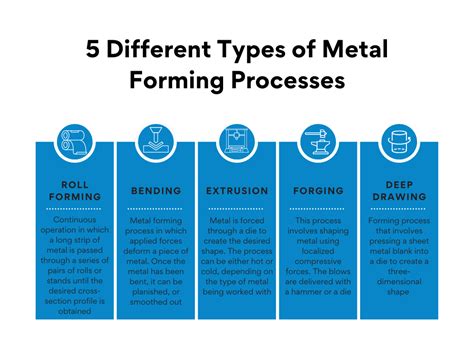

3 · types of metal fabrication processes

4 · manufacturing processes for metals

5 · manufacturing methods for metals

6 · manufacture of fabricated metal products

7 · basic metal fabrication

Our shop does work for Xometry regularly. We use it as kind of a fill in while we have machine time open. Do one offs and production runs. This year we're looking to do 100-150K with them. With the jobs we take, you need a QC program set up with verified calibrated measuring tools and CMM.

The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies. Sheet metal is highly compatible with the process, allowing custom sheet metal . Understanding the Role of Metal Type. Different types of metals‘ physical and chemical properties are distinct and affect the different finishing operations in varying degrees of effectiveness. For instance, steel, the most common ferrous metal, usually goes through galvanizing in order to prevent screen damage since it rusts very quickly owing to its iron .

Fabrication is not a single-shot process. It is a combination of different tools, processes, and techniques. So, manipulating a raw sheet into final shapes involves different sheet metal fabrication techniques, from cutting to .

Precision sheet metal parts. Precision sheet metal fabrication process develops accurate metal parts. The process consists of design, the cutting of materials, forming, component joining, and surface finishing. . or plasma techniques are normally used in precision metal fabrication. These techniques reduce material wastage and provide the . Sheet Metal Fabrication Techniques for Auto Parts. These techniques cut sheet metal parts into smaller pieces of varying dimensions. Laser, plasma, and shearing are common sheet metal auto parts cutting methods. Laser Cutting. Laser cutting is a common sheet metal technique used in automotive manufacturing because of its high precision.

An overview of metal fabrication, types of fabrication, and tips for choosing a custom fabricator for a project. For Buyers. Supplier Discovery. . Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal .Laser-based 3D printing enables the layer-by-layer construction of metal parts, allowing complex geometries and rapid prototyping. Future Horizons and Emerging Trends. Anticipated Advancements: . The ascendancy of laser metal fabrication techniques heralds a new era in manufacturing, where precision, speed, and versatility converge to .

what are fabricated metal products

Sheet Metal Fabrication Techniques. Sheet metal fabrication technology encompasses a wide range of cold processing techniques for sheet metal.. As the use of sheet metal components continues to grow, sheet metal processing technology has become an integral part of product development. Designers must have a good understanding of the properties of .

The auto part industry needs modern automotive parts to meet the increasing design requirements, which can be effectively managed using sheet metal fabrication techniques. The introduction of computer-aided design (CAD) technology into sheet metal fabrication in the automotive industry also improved the precision and accuracy of the . Sheet Metal Fabrication From Manor Tool. Sheet metal fabrication involves six main techniques that can be used separately or in combination to produce the desired part. With over six decades of experience, Manor Tool serves various industries with quality metal stamping and fabrication from our Illinois facility.

Before a raw metal material can be used for manufacture and assembly, it still needs to undergo different types of metal fabrication techniques. These processes can vary, depending on the purpose of the metal, but they can nevertheless be found in a number of structural, industrial, or decorative applications.

Popular Techniques in Sheet Metal Fabrication Punching. As its name implies, punching involves using a punch press to push a tool through a metal part. This force creates a hole in the workpiece via shearing. In the case of high production volumes, punching is a particularly cost-effective option for creating holes in metal parts.

types of steel fabrication

Techniques in Metal Fabrication Cutting Techniques. Cutting is a fundamental process in metal fabrication, where raw metal is divided into desired shapes and sizes. . Digital twins, virtual simulations, and real-time monitoring are becoming integral parts of the metal fabrication workflow. Challenges in Metal Fabrication 1. Skilled Labor Shortage

Metal fabrication is the process of shaping and manipulating metal into desired structures or components. It involves various techniques such as cutting, bending, and assembling, which transform raw materials into finished products. Metal Fabrication Techniques. Metal fabrication encompasses several techniques, including: Cutting Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet metal design guidelines to ensure manufacturability.

Author Eddie Paul is a master at sheet metal fabrication and in this book shares with readers the techniques to shape their own sheet metal creations. Sheet Metal Fabrication: Techniques and Tips for Beginners and .Metal Fabrication Processes and Techniques. Metal fabrication is a versatile industry that encompasses various processes to create custom metal products. From forging and casting to machining and stamping, these techniques allow fabricators to work with materials like steel or aluminum in creating both stock items and customized fabricated .

Sheet metal finishing enhances both the appearance and functionality of metal parts. The right finish prevents rust, increases wear resistance and creates an attractive surface texture. Modern finishing techniques like powder coating, .When manufacturing metal parts, companies use many fabrication techniques and tools. Different processes and tools give different results and limitations, and understanding what is available helps determine the best process for a project. This blog post covers the most common metal fabrication techniques and tools among metal fabricators.

What is Sheet Metal Fabrication? Sheet metal fabrication is any process that involves assembling or manufacturing raw sheet metal.One or more fabrication processes can be used to produce the desired part, depending on the material and specifications of the project.. Sheet metal fabrication is a manufacturing technique that involves making products from flat metal sheets. “The capabilities of sheet metal fabrication lie in its diversity of techniques; it combines cutting, bending, welding, and other techniques to craft the final part.” Fabrication is not a . Metal fabrication processes are the specific techniques used to shape and form metal parts. Let's explore some of the most common metal fabrication processes in detail. Casting . Casting is a metal fabrication process that involves pouring molten metal into a mold to create the desired shape. Key Takeaways Metal fabrication is a complex and varied process that involves numerous techniques, from welding to cutting. It is crucial in the automotive, aerospace, and construction industries. Understanding its applications can aid in selecting the appropriate method for specific industrial needs. Metal fabrication blends craftsmanship and technology, employing .

types of metal processing

Korgancı and Bozkurt [41] summarized research findings on additive solid-state FSP methods, emphasizing recent developments in the microstructure and mechanical properties of aluminum, steel, nickel, titanium, magnesium alloys, and composites deposited through these techniques. Another review by Yu and Hahn [70] conducted an in-depth literature survey on . Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high strength-to-weight ratio, durability, and versatility. This guide will provide a comprehensive overview of precision sheet metal fabrication techniques, applications, and best practices.

Fabricating Aircraft Part. First, aerospace sheet metal fabrication involves manipulating sheet metal to make aircraft parts and components. Recently, many aircraft manufacturers, such as Lockheed Martin, General Electric, Airbus, Leonardo, Boeing, and Raytheon, use different sheet metal fabrication techniques. It is due to: Explore the world of metal fabrication, learn the techniques, and see welding examples. Discover the process of making something from different parts. 541-753-4090; [email protected]; . It is a process used to shape metal parts to form specific geometries without adding or subtracting material. This process involves: Applying mechanical forces . Metal fabrication is the creation of metal parts or structures from a variety of metal materials through different processes. The metal materials come in sheet, bar, plate, or other forms and can be made into specific shapes and dimensions. . There are various types of fabrication processes or techniques applied in modern production, choose .

2 gang junction box cover

2 door steel wall cabinet

OM-AMU series non-metallic fiberglass enclosures are designed to insulate and protect electrical controls and components in both indoor and outdoor applications and are especially well suited for higher temperatures and corrosive environments. These NEMA 4X (IP66) fiberglass JIC .

metal part fabrication techniques|manufacturing processes for metals