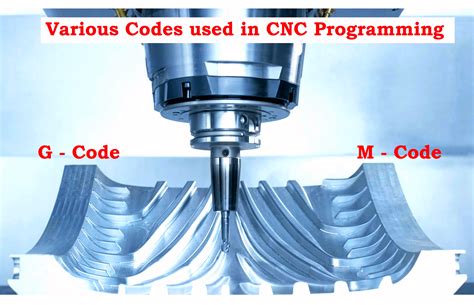

programming language for cnc machines CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool . I am trying to single point a M30 x 3.5 thread and the thread is not coming out right. I've tried running the thread on 2 different cnc lathes (Ameri-Seiki TC-5XL with a Fanuc OTC control and a Mori-Seiki SL-6 with a 6T control).

0 · types of cnc programming

1 · simple g code program

2 · how to program cnc machines

3 · g code for cnc machine

4 · cnc programming languages list

5 · cnc programming for beginners

6 · cnc milling machine programming

7 · basics of cnc programming

The answer is that the Red Wire is the Hot Wire from the switch itself. You are wiring your fixture into a junction box where buku wires come together. Hook the white to white, ground to ground and RED to the BLACK Light Fixture Wires.

types of cnc programming

CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool . For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how . CNC command codes are core to modern manufacturing processes. CNC machines operate on these CNC programs, hence why manufacturers need them in different manufacturing processes. CNC G and M codes are commonly used software programming languages in CNC machining, depending on the tasks that the machine performs. However, .

It's the language that directs CNC machines on how to execute various tasks, from cutting and drilling to milling and shaping. But what exactly are the types of CNC programming and how do they differ? Let's delve into this fascinating .

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by automating complex machining processes. One key aspect of CNC machining is the programming language used to control these machines. There are several CNC programming languages available, each with its unique features, advantages, and applications.

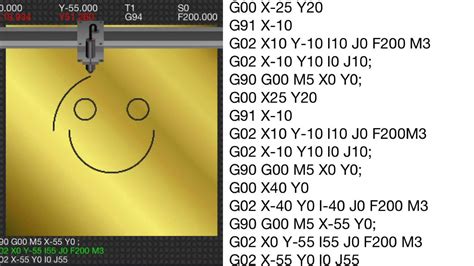

EXAMPLE 2: Sentence in G-code: G21 G17 G55 Explanation: Setting programming units to millimeters; Selecting XY working plane; Selecting G55 coordinate system. Sentence in G-code: G43 H1 Z100 Explanation: Setting tool height offset compensation to H1 (“H1” is a position where the value of tool height is saved in the memory of CNC machine) and .CNC machine programming languages are an essential aspect of CNC machining, enabling precise and accurate manufacturing processes. Choosing the right programming language for your manufacturing needs depends on several factors, such as the complexity of the manufacturing process, the machine's type, and the overall cost. . The production of precision parts goes beyond merely possessing a CNC machine; it requires a programming language that the machine can interpret—specifically, G-codes and M-codes. In 1952, to address the aviation industry’s need for accurate part machining, John T. Parsons partnered with IBM (International Business Machines) and MIT .

Introduction to CNC Programming: CNC (Computer Numerical Control) machines have transformed the manufacturing industry by allowing precise control over machine tools through programming. Instead of manually operating machines like lathes, mills, or grinders, CNC technology lets manufacturers automate the machining process by feeding the machine a .

G-code is a language used by CNC machines to interpret and execute specific movement instructions. The code is a series of alphanumeric commands that dictate the actions of a machine, such as linear movements, tool changes, spindle speeds, and coolant activation. . CNC programming itself is inherently complex, and as the core language of CNC . This language laid the foundation for CNC machine programming as we know it today. During the same era, the RS-274 programming language, commonly known as G-code, emerged as a refinement of APT. G-code quickly became the standard programming language for CNC machines due to its concise and convenient instructions.

Section 4: Common Programming Languages for CNC Machines \[Approx. 300 words] CNC machines use different programming languages to control their operations. G-code, the most widely used language, provides instructions for various CNC functions, such as tool movement, feed rates, and spindle speed. M-code, on the other hand, controls machine .Just go straight for the VF3 (VM3 is slightly better). CNC programming is not hard if you’re computer literate. Conversational machines are sold as an easier alternative to G code. Mainly for old people that are scared of computers. They’re not easier. They’re super clunky and you have to tie up the machine for programming.G-code (also RS-274) is the most widely used computer numerical control (CNC) and 3D printing programming language.It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications.The G stands for geometry. G-code has many variants. G-code instructions are provided to a machine controller (industrial computer) . Next, the design is taken to Computer-Aided Manufacturing (CAM) software. The CAM software converts the previous instructions to others that are understandable by the CNC machine. There are several programming languages for CNC machining, but the most popular is G-Code. This language is based on alphanumeric codes.

G and M codes are the basic programming languages for CNC machines. The codes automate the processes by giving the CNC machine a standardized set of step-by-step instructions to follow without human intervention. This allows precise and repeatable cutting of complex 3D parts. G codes control the machine's movements. M codes manage extra . APT programming language is a language for defining tool paths on CNC machines. APT is an acronym for Automatically Programmed Tool. It was the predecessor to today’s CAM software, created in the late 1950s to define .

simple g code program

CNC programming is the process of converting a 3D model into machine-readable instructions in order to perform automated machining operations. Learn more about it here. . (CAM) software to convert a CAD file . It is a programming language that tells CNC machines how to move, position, and operate various tools during the machining process. G-code consists of alphanumeric instructions that control aspects such as tool . Many perceive CNC programming as a labyrinthine domain, but it’s much like any other language – albeit one spoken between humans and machines. This expanded discourse provides an in-depth look into CNC programming, helping novices and experts alike navigate the nuances of this intricate domain. Note: The terms “digital twin” and “finite element analyses” refer to a virtual model of a process, product, or service, and a numerical method for predicting how a product reacts to real-world forces, respectively. Chapter Content: CNC Horizontal Boring Machines and G-Code Programming The Role of G-Code in CNC Horizontal Boring Machines. G-Code is the .

The programming language used by the CNC machine tool is essentially APT (Automatically Programmed Tool) language, which is a high-level programming language, its main founder is the American scientist Douglas T. Ross,. Douglas T. Ross was born in Guangdong, China and grew up in New York, USA.

G-Code is the most commonly used CNC machine programming language. It acts as a controller and governs the movement of the machine to create the desired CNC machined product. On the other hand, M-Code is utilized for specific applications and controls various machine functions, such as initiating or stopping actions or programs. . CNC machining programming is the process of creating detailed instructions that guide a machine to perform precise CNC machining operations. These instructions are written in a language known as G-code, the G-code tells the machine how . A: G-code or geometric code is a programming language used to instruct CNC machines, including those running on Marlin firmware. It comprises of code commands that direct the machine on how to move its axes, control speed as well as perform various functions. CNC (Computerized Numerical Control) machining is a technology that allows machines to perform precise cutting, engraving, drilling, or milling operations based on preset instructions, m-code is a component of the CNC programming language used to control various functions during the machining process. This article provides a comprehensive understanding .

This book covers CNC programming, speeds and feeds, carbide tooling selection and use, workholding, and machine setups. The practical, understandable, step-by-step approach makes learning how to program a CNC machining center (milling machine) a much easier and less frustrating task. All standard M- and G-codes as well as canned cycles are covered. Now that you know a bit more about what programming language a CNC machine uses, you’ll want to be able to answer the question, what is M-code in a CNC machine, and what is G-code for a CNC machine. G-code primarily deals with the movement and positioning of a CNC machine, while M-code is related to auxiliary functions. .

2020s: AI continues to be integrated into CNC machining and programming, leading to improved efficiency, precision, and productivity in the manufacturing industry. The use of AI in CNC machining and programming has become increasingly widespread. ChatGPT: CNC Programming Through AI-Language Models

What are the Benefits of CNC Machining? The accuracy of the CNC machine ensures consistent product quality. The process is more precise than manual machining and can be repeated in the same manner over and over again. Increased production speed and increased efficiency.

programming language for cnc machines|basics of cnc programming