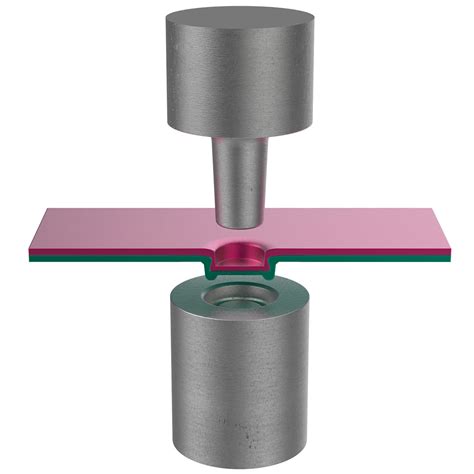

sheet metal joining without fasteners “Clinching” is a non-fastener, non-adhesive technique used to assemble two or more different pieces together by cold forming (pressing) the materials together. The connection is a permanently formed round or square . $108.99

0 · sheet metal latch creation

1 · sheet metal clinching joint

2 · seam joint in sheet metal

3 · interlocking sheet metal joints

4 · interlocking sheet metal design

5 · crimping process in sheet metal

6 · clinch lock sheet metal

7 · alternatives to sheet metal

Solar panel junction boxes are vital components of any solar energy system, providing necessary connections for the solar panels and other components of your system. They also provide important safety measures to protect your home or business against safety hazards like electric shocks.

sheet metal latch creation

RIVCLINCH is a method of assembling sheet metal without welding or fasteners, using a deformation process that creates an interlocking of two or more metal laye. How to fasten sheet-metal parts without fastening hardware. Folding and adding bending tabs is one of the easiest and most economical way of making moderately strong joints in. The clinching process is a method of joining sheet metal by localised cold-forming of the materials. RIVCLINCH® is a cost-effective, environmentally friendly.

Fasteners like nuts, bolts and screws offer a non-permanent solution for joining sheet metal, allowing you to easily disassemble parts without damaging them. They do require a level of precision in creating aligned holes through which .

“Clinching” is a non-fastener, non-adhesive technique used to assemble two or more different pieces together by cold forming (pressing) the materials together. The connection is a permanently formed round or square .

By means of clinching joining technology, steel and stainless steel materials as well as aluminium and other non-ferrous materials are joined together without welding or fasteners. Join metal parts in a cost effective and sustainable way .The clinching process is a method of assembling sheet metal without welding or fasteners. With this joining technique, metal parts are deformed locally without the use of any consumables. Easily releasable mechanical fastening of sheet metal without fasteners is now a reality. The snap-fit connections make that possible. But be aware that new possibilities open up when plastic deformation is allowed or .

The following factors affect the selection of the type of screw to join sheet metal parts. Sheet Metal Material. Experts recommend self-tapping fasteners for hard materials ( CRCA, SS), whereas machine screws are the best choice for softer .

Ways to join sheet metal without fasteners. You can join sheet metal: Using a mechanical method, such as clinching or hemming. By welding the two pieces of metal together. There are various welding techniques, each with advantages and disadvantages, such as MIG, TIG, spot welding, or laser welding. Thermally using heat, such as brazing or .8.1 Mechanical joining without additional fastener 8.1.1 Hemming 8.1.1.1 Hemming process 8.1.1.2 Hemming systems 8.1.2 Clinching 8.1.2.1 Clinching with local incision . and flanging operation to join two sheet metal parts (generally outer and inner closure panels) together. Typical parts for this type of assembly are hoods, doors, trunk lids .

This 100% pneumatic tool is outstanding for joining large and thick sheet metal frames and profiles, such as ventilation ducts, door frames and much more, to a total thickness of 4.5 mm (construction steel). . RIVCLINCH® Metal joining without fasteners pdf 823 KB English; RIVCLINCH® Automation E When clinching electrifies - energy-efficient Appliance engineers have several options for joining sheet metal, including screws, rivets, welding, bonding, clinching and folding. Which is best depends on the material, its thickness and the application requirements. . Clinching is a popular way to join sheet metal without screws, bolts or rivets. It’s used to assemble all types of large .This 100% pneumatic tool is outstanding for joining large and thick sheet metal frames and profiles, such as ventilation ducts, door frames and much more, to a total thickness of 4.5 mm (construction steel). . RIVCLINCH® Metal joining without fasteners pdf 823 KB English; RIVCLINCH® Automation E When clinching electrifies - energy-efficient Clinching is a fastening process used to join two or more pieces of sheet metal media continuously without any requirement of bolts, screws, or heat. The force brings interaction on edges, which makes it appropriate on thin sheet of metal. . Employment of appropriate tools and equipment bears a significant effect on the quality as well as the .

Hemming is one of the best ways to join two sheet metal parts without fasteners. This process needs to be adapted in joining two sheet metal parts into a sub-assembly before assembling of internal components. . It is a cost-effective process of joining sheets of metal without the sparks, fumes, and potential material damage that can be caused .The clinching process is a method of assembling sheet metal without welding or fasteners. With this joining technique, metal parts are deformed locally without the use of any consumables. Multiple materials, with different individual thicknesses can be assembled at the same time based on this cost effective, fast and clean process : steel and .

sheet metal clinching joint

There are several situations where you may have to join metal together and not be able to use mechanical fasteners like nuts or bolts. There are other ways t. Joining Sheet Metal without Fasteners. March 22, 2021 . Bollhoff Rivclinch® Catalog, Click here to Download Catalog. Bollhoff Rivclinch® is a specialized joining technology used for steel, stainless steel, aluminum and other non-ferrous materials. “Clinching” is a non-fastener, non-adhesive technique used to assemble two or more different .Sheet metal joining is a crucial aspect of fabrication that can make or break the durability, functionality, and aesthetics of your projects. . and create a clean appearance without visible fasteners. Modern structural adhesives can provide strength comparable to welded joints in many applications. For bonding metal, use a metal epoxy like JB . When choosing fasteners for sheet metal projects, several key factors come into play. . permanent threads in thin metal without adding a bulk in your sheet—ideal where traditional threading might not be an option due to the thin material . strong fastening. They work well for joining different materials and offer consistent reliability in .

This 100% pneumatic tool is outstanding for joining large and thick sheet metal frames and profiles, such as ventilation ducts, door frames and much more, to a total thickness of 4.5 mm (construction steel). . RIVCLINCH® Metal joining without fasteners pdf 823 KB English; RIVCLINCH® Automation E When clinching electrifies - energy-efficient

Laser cutting and bending sheet metal are popular in many industries. In the vast majority of these cases sheet metal is mounted by using fasteners such as b.The clinching process is a method of assembling sheet metal without welding or fasteners. With this joining technique, metal parts are deformed locally without the use of any consumables. It creates an interlocking of two or more metal layers. Painted or coated metal sheets can also be joined by this method without damaging the surface. Ducts shall not be joined with screws or similar fasteners that protrude more than 1/8 inch (3.2 mm) into the inside of the duct. That pretty much eliminates screws since the taper end of the sheet metal screw is longer than 1/8 inch. As for using a 1/8" pop rivet with a crimped end joint connection, well good luck making that work.Hemming is another technique that can be used to join sheet metals without the use of fasteners. The edges of two sheets are folded to create curved ‘hems’ that can interlock with one-another, creating a temporary join. 8. Snap Fits. Metal sheets can be joined using snap-fits, which use spring force to hold parts together.

Captive nuts are a type of fastener that is designed to be held in place within a structure, allowing a bolt to be threaded into it without the nut spinning. . The Best Solution for Joining Sheet Metal Parts Without Welding. Captive nuts are a fantastic solution for many assembly challenges, offering a simple, effective way to join metal . In this article we’ll discuss a variety of common methods for joining your laser cut and waterjet parts. Whether it’s as common as a nut and bolt, or something more specialized, like an integrated fastener from our hardware insertion service, we’ll hit the high points for each method, and give recommendations on when it’s a good idea to use it, or not.

When joining thin sheets with classic sheet metal screws with ST threads, it is often necessary to use nut elements. Direct fastening with QUICK FLOW® Plus is more benefical for the lightweight construction methods used in many industries today, as it enables secure and long-lasting fastening without additional components such as nuts.This 100% pneumatic tool is outstanding for joining large and thick sheet metal frames and profiles, such as ventilation ducts, door frames and much more, to a total thickness of 4.5 mm (construction steel). . RIVCLINCH® Metal joining without fasteners pdf 823 KB English; RIVCLINCH® Automation E When clinching electrifies - energy-efficient 24 solutions for fastening sheet metal components (and tubes) to each other, including non-sheet-metal components.Parts produced by Suplacon in Emmeloord, Th.

In the realm of sheet metal fabrication, the choice of joining method plays a pivotal role in determining the quality, efficiency, and cost-effectiveness of the final product. . reducing production time and increasing throughput. The process involves interlocking two metal sheets without the need for fasteners or adhesives. The gun’s jaws .

The most recognizable method of joining two parts together would be with bolt and nut connections. Bolt-nut connections are generally used for detachable mounting of components and sheet metal parts. A nut is retained based on creating sufficient friction within the thread and between the interfaces of the fastener and Sheet Metal.

The clinching process is a method of joining sheet metal by localised cold-forming of the materials. RIVCLINCH® is a cost-effective, environmentally friendly.Clinch systems are innovative joining solutions used in various industries for fastening and joining two or more pieces of sheet metal or similar materials without the need for additional components such as welding materials, adhesives, or rivets.

Are you interested in working at a metal fabrication shop? Hone your skills at Metaltech Products. We offer competitive wages and benefits, including retirement plans, insurance options, and paid vacation.

sheet metal joining without fasteners|sheet metal latch creation