coolant oil for cnc machines Coolant lubricates the cutting zone and facilitates efficient chip removal. Without coolant, chips remain in the work area, which causes chip recutting and chip clogging — and results in reduced productivity, excess .

$1,721.25

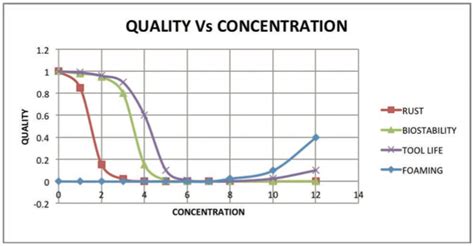

0 · machine coolant concentration chart

1 · lubricant used in cnc machine

2 · how to maintain machine coolant

3 · coolant system for milling machine

4 · coolant ph levels chart

5 · cnc oil mist cooling system

6 · cnc machine coolant suppliers

7 · cnc machine coolant health problems

Step up your dart playing with the Viper Hideaway Steel Tip Cabinet and Dartboard! Featuring a stylish cabinet to store and protect your dartboard, this powerful dartboard is the premium choice for any darts enthusiast! Get ready to soar to higher levels of darts performance with the Viper Hideaway Steel Tip Cabinet and Dartboard!

Virtually all CNC machining centers and lathes today are designed to use water-based fluids, but most Swiss-style screw machines use straight oil. There are three categories of coolants that sometimes overlap: soluble oils, .In this comprehensive guide, we will explore the significance of coolant oils in CNC machines, their types, properties, applications, and tips for selecting and using the best coolant oil for .Coolant oil is not just a lubricant; it also helps in dissipating heat, reducing friction, and preventing corrosion in CNC machines. Using the right coolant oil can result in improved cutting . Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant .

machine coolant concentration chart

lubricant used in cnc machine

Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut . Coolant lubricates the cutting zone and facilitates efficient chip removal. Without coolant, chips remain in the work area, which causes chip recutting and chip clogging — and results in reduced productivity, excess .

Coolants play a vital role in CNC machining by providing the following benefits: Heat management: Coolants dissipate heat generated during machining, preventing thermal damage to both the cutting tool and workpiece. .

Cutting fluid, also known as coolant, cutting oil, cutting compound, or lubricant, is a kind of industrial liquid used in process of metal cutting like CNC machining to cool and lubricate .

CNC machine coolants play a vital role in achieving optimal efficiency in a CNC shop by reducing heat build-up, lubricating cutting tools, and preventing discoloration and . No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select a . Virtually all CNC machining centers and lathes today are designed to use water-based fluids, but most Swiss-style screw machines use straight oil. There are three categories of coolants that sometimes overlap: soluble oils, synthetic fluids and semisynthetic fluids.

In this comprehensive guide, we will explore the significance of coolant oils in CNC machines, their types, properties, applications, and tips for selecting and using the best coolant oil for your operations.

Coolant oil is not just a lubricant; it also helps in dissipating heat, reducing friction, and preventing corrosion in CNC machines. Using the right coolant oil can result in improved cutting performance, increased tool life, and better surface finishes. Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant in CNC Machining Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut 7227 . Coolant lubricates the cutting zone and facilitates efficient chip removal. Without coolant, chips remain in the work area, which causes chip recutting and chip clogging — and results in reduced productivity, excess material removal, undesirable surface finish, or issues with features like internal threads.

Coolants play a vital role in CNC machining by providing the following benefits: Heat management: Coolants dissipate heat generated during machining, preventing thermal damage to both the cutting tool and workpiece. Tool life extension: By reducing friction and heat, coolants minimize tool wear and extend tool life, reducing overall costs.Cutting fluid, also known as coolant, cutting oil, cutting compound, or lubricant, is a kind of industrial liquid used in process of metal cutting like CNC machining to cool and lubricate cutting tools and work pieces. CNC machine coolants play a vital role in achieving optimal efficiency in a CNC shop by reducing heat build-up, lubricating cutting tools, and preventing discoloration and failure in various machining processes such as CNC milling, turning, or drilling.

how to maintain machine coolant

No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select a .

Virtually all CNC machining centers and lathes today are designed to use water-based fluids, but most Swiss-style screw machines use straight oil. There are three categories of coolants that sometimes overlap: soluble oils, synthetic fluids and semisynthetic fluids.In this comprehensive guide, we will explore the significance of coolant oils in CNC machines, their types, properties, applications, and tips for selecting and using the best coolant oil for your operations.

Coolant oil is not just a lubricant; it also helps in dissipating heat, reducing friction, and preventing corrosion in CNC machines. Using the right coolant oil can result in improved cutting performance, increased tool life, and better surface finishes.

Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant in CNC Machining Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut 7227 . Coolant lubricates the cutting zone and facilitates efficient chip removal. Without coolant, chips remain in the work area, which causes chip recutting and chip clogging — and results in reduced productivity, excess material removal, undesirable surface finish, or issues with features like internal threads. Coolants play a vital role in CNC machining by providing the following benefits: Heat management: Coolants dissipate heat generated during machining, preventing thermal damage to both the cutting tool and workpiece. Tool life extension: By reducing friction and heat, coolants minimize tool wear and extend tool life, reducing overall costs.

Cutting fluid, also known as coolant, cutting oil, cutting compound, or lubricant, is a kind of industrial liquid used in process of metal cutting like CNC machining to cool and lubricate cutting tools and work pieces.

Rubber edge trim is a highly flexible trim made of dense neoprene rubber. You can use edge trim for sheet metal or sharp edges. It is available in black. Edge Trim Plus features four specially-designed sets of flexible gripping tongues for easy installation and maximum grip retention.

coolant oil for cnc machines|how to maintain machine coolant