cnc machining one off chuck adapters 5: Thread chuck off spindle It's here that it threaded off about 25mm and is still attached. Won't come off, just spins. 6: Remove chuck travel limiter from chuck body 7: Remove chuck body. The jaw actuator just rotates on the drawbar. I can see slots on a ring that is butted up against the actuator that spins with the jaw actuator.

Order parts and accessories for all types of CNC machines. Cutting tools, workholders, toolholders, measurement and calibration devices, and more.

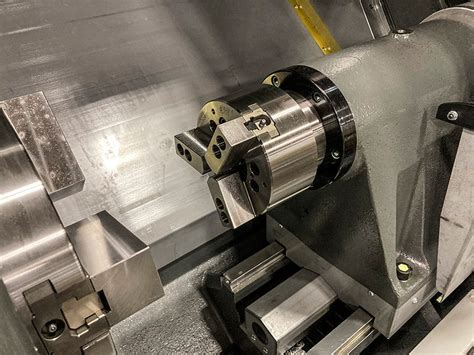

0 · turning center sub spindle chuck

1 · sub spindle chuck

2 · cnc sub spindle chuck

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

It's a little trickier finding a used chuck/collet chuck with the 100mm mount, most will have an A2, which will not work without an adapter plate. Also for sub-spindle work, most . Going to make an adapter to mount a 12" 4 jaw to my CAZENEUVE. Posting in the general section as the material is the focal point not the type of lathe. Those not familiar with . I picked up a new in the box ZA6-8 MMK chuck off ebay a year or so ago for 0. Nice chuck and definitely made in Japan rather than elsewhere. Seems odd LMC would list the Z series which is a flatback and not the direct mount ZA's. In power chucks it seems like the direct mounts would outsell flatbacks by 10 to 1. Then the tube should easily unscrew from the actuator. Then you may have to remove the tailstock to get clearance to take the chuck with tube attached out the front of the machine. In one instance, I was called in to remove a stuck chuck that the operator has cross-threaded the draw tube on while switching from a collet nose back to the chuck.

Now all i have to do is spin off the hydraulic chuck, spin on the adapter plate, draw the tube in until it contacts the spindle nose, bolt the adapter to the spindle, bolt the manual chuck to the adapter and make parts. After 2 changes of chucks it seems to repeat fine, and doesn't throw off any of my production jaws for the hydraulic chuck.

5: Thread chuck off spindle It's here that it threaded off about 25mm and is still attached. Won't come off, just spins. 6: Remove chuck travel limiter from chuck body 7: Remove chuck body. The jaw actuator just rotates on the drawbar. I can see slots on a ring that is butted up against the actuator that spins with the jaw actuator. More anti-seize and mount the chuck. By the way, if you're just mounting a collet-chuck, it shouldn't be necessary to pull out the drawtube. There should be a threaded adapter that screws onto the drawtube end, then mount the collet chuck. The collet will pass through the chuck and screw into the adapter.

Back plate chuck adapter. Thread starter IndGild; Start date Oct 5 , 2014; Replies 0 . Joined Mar 2, 2007 Location ct. Oct 5, 2014 #1 First off all , i would shot in the leg guy who invented metric and inch system of measuring. I would by law forbid to use either millimeter or inch allen wrenches/screws. Next thing is spindle nose . This will push the chuck off of the spindle or adapter plate. Dont worry, the drawtube will support it okay. Before unthreading the chuck, slip fit a 12" hunk of barstock through the chuck center into the drawtube to support and pilot the chuck while unscrewing. - makes assembly easier, too. CNC Machining . How to remove this #(#!*# sub spindle chuck ?? . Got the "chuck" part off, but can't figure out how to remove the mount for the chuck..the extension tube to the collet closer has to come off first, but damned if I can see what's holding it on.maybe just press fit ? . One end is screwed to the machine drawtube, the other . 5. QuickFlex adapter; 6. One-hand wrench; 7. Thread for QuickFlex adapter and collet nut; 8. Short taper for radial centering and axial support of the QuickFlex adapter; 9. Taper of the ER collet chuck; 10. Polygonal torque transmission for QuickFlex adapter; 11. Radial bending support of the QuickFlex adapter for high stiffness under load

turning center sub spindle chuck

4 Pieces High-Carbon Steel Collet Die Grinder Chuck Driver Adapter 1/4" to 1/8" CNC Engraving Bit Router Converter for Engraving Machine Tool - Amazon.com. . convenient returns with at least one free return option: no shipping charges. All returns must comply with our returns policy. . For CNC machine tool chuck conversion, conversion size . It should be possible if you make the adapter say 2" thicker or so than a typical chuck adapter to push the 6" chuck farther away from the A2-6 face. This would leave room for the standard drawtube to still fit well behind the small hole in the 6" chuck. Then machine up a drawtube adapter to connect to the existing drawtube and the new chuck. Can't believe I didn't find anything from searching. I got a screaming deal on a collet chuck, but the nut doesn't match my drawtube, so I'm thinking to just make one. 60mm x 2mm thread. What would be the best material? I'm hoping to get this done quick, so I would rather not send it out to get hardened. 4140PH? 1045? 17-4? Or A2 or something?

You can make a new nut or buy one. D. Delw Stainless. Joined Jan 8, 2019. Feb 13, 2020 #3 SRT Mike said: . WTB Collet Chuck drawtube adapter for CNC. Chips Everywhere; May 16, 2023; Tooling, Parts and Accessories For Sale or Wanted; Replies 0 . CNC Machining. ABOUT PRACTICAL MACHINIST. That Mazak would face of the part, drill it ,turn the O.D. 7nd shoulder, part it off and the bar puller would pull it out a little bit farther than the length of the part.<( with the automatic chuck it would un-chuck and re-chuck when needed) Then face it off and go again. Use pie jaws and bore them to hold a small manual 4 jaw chuck when needed. Slide the foot pedal out of the way when using the 4-jaw so you do not drop the chuck in the conveyor on accident. I have 4 jaw chucks of various sizes to use depending on the job at hand. The 3 jaw power chuck we have uses an adapter plate on the A2-8 spindle mount, while the new chuck won't need that adapter. This means that the draw tube for the 3 jaw power chuck is a little longer. I measured and determined that if I shorten the drawtube approx 1.00" I will be able to use it for both chucks, as opposed to buying a different .

Optional Chuck Shaft: 5mm, 6mm, 8mm, 10mm, 12mm. 1× Drill Chuck. For milling machine, lathe, drilling machine, wood working machine. . B12 Drill-Chuck W/ Wrench Clamping Range 1.5-10mm CNC Machine Convert Adapter. onybuyone (794) 97.2% positive . they apologized for the delay and adjusted a couple dollars off the price to compensate, would .

A member here was kind enough to sell me a new ATS S20 collet chuck at a reasonable price. Now all I need is the draw tube adapter nut for and HAAS SL20. I know I can figure one out and make it, but instead of reinventing the wheel I was wondering if anyone here had made one and has the specs.

Just curious if anyone knew of any place that made a A2-5 spindle to D1-4 chuck adapter. Had an idea I was thinking about trying (3jaw manual on the CNC to allow larger material through the spindle with the draw tube removed) - but didnt want to go buy a chuck without trying the idea first, and all I have are d1-4 chucks with the D1-4 integral to the chuck body. 𝐋𝐮𝐨 𝐤𝐞 5 Pieces Collet Adapter Die Grinder Chuck Driver Adapter 1/4" to 1/8" CNC Engraving Bit Router Converter for Engraving Milling Machine Tool . convenient returns with at least one free return option: no shipping charges. All returns must comply with our returns policy. . For CNC machine tool chuck conversion, conversion .

sheet metal fabrication podcast

I have a royal 5c chuck on mine, and really wish I would have got a 16C and then an adapter down to 5c to use the cheaper collets on the small stuff. The other thing to double check when purchasing a collet chuck is the length. In the size for my machine there was a 5" and a 6" length chuck. I opted for the 5" thinking it would be more rigid. The adaptor is good because I have several 5C collets, but I'm considering a collet chuck and would also like a chuck. I see some collet chucks that have the threaded nose that will fit on the A2-5 spindle nose I have, but I have not seen one with the correct threaded part that fits the drawbar would pull the 5C in 𝐋𝐮𝐨 𝐤𝐞 5 Pieces Collet Adapter Die Grinder Chuck Driver Adapter 1/4" to 1/8" CNC Engraving Bit Router Converter for Engraving Milling Machine Tool 4.4 out of 5 stars 10 2 offers from .80

sheet metal fabrication plymouth ma

One is fitted to holding a rather useful Jacobs RubberFlex 900 series master chuck, one collet. "Useful" as I have another for the 10EE's, plus somewhere around 3 sets of collets and "butt plugs". The other held a doubly-useless French "Handy" 200 mm / ~ 8" 3-Jaw chuck, two-piece jaws. CNC Machining . CNC Collet Chucks. Thread . I made a short one completely out of uhmw for 1.75 and it works pretty good. When I get a PO for these parts I'll have to make them, should cost around 0 to make 2 of them. . Royal makes an A11 to A8 adapter that would allow you to use an off-the-shelf chuck. They're nice but $$$. Y. yardbird . I will be buying larger sizes in 16C, but would like to hear from anyone who has a collet adapter, either 16C or 3J, to 5C and how they like it. I can get three, maybe four 16C collets for the price of the adapter so I am considering this carefully. Quick Change 16C Collet Chuck To 5C Collets Regards, Ray

CNC Machining . Hydraulic 3 jaw chuck removal, draw tube is spinning also . Then when you unclamp the chuck, the actuator should come off the adapter or should be able to be pulled off the actuator. Then you should be able to tighten the locknut on the drawtube. . I have had to cut more than one drawtube to get a chuck off. I don't use .

sub spindle chuck

cnc sub spindle chuck

Look through the wide range of wholesale lathe cnc turning part listings on Alibaba.com to find the right provider for your machining needs. All kinds of machining services are covered here.

cnc machining one off chuck adapters|cnc sub spindle chuck